DRUG SAFETY

FDA Should Implement Strategies to Retain Its Inspection Workforce

Report to Congressional Committees

November 2024

GAO-25-106775

United States Government Accountability Office

View GAO‑25‑106775. For more information, contact Mary Denigan-Macauley at (202) 512-7114 or deniganmacauleym@gao.gov.

Highlights of GAO‑25‑106775, a report to congressional committees

November 2024

DRUG SAFETY

FDA Should Implement Strategies to Retain Its Inspection Workforce

Why GAO Did This Study

FDA, an agency within the Department of Health and Human Services (HHS), inspects foreign and domestic drug manufacturers as a key oversight tool to ensure the safety and quality of drugs marketed in the U.S. In response to travel disruptions caused by the COVID-19 pandemic, FDA paused many inspections and relied on the use of alternative inspection tools to oversee drug manufacturing.

The Consolidated Appropriations Act, 2023, includes a provision for GAO to report on the status of FDA’s foreign drug inspections and its use of alternative tools. This report describes the status of FDA in-person inspections, describes FDA’s use of alternative tools, and examines FDA investigator vacancies and the agency’s efforts to address them, among other objectives. For this work, GAO examined FDA data and documents and interviewed FDA officials and investigators who conducted inspections and used alternative tools. GAO also reviewed documents from and interviewed six stakeholder groups that represent the major components of the drug manufacturing industry.

What GAO Recommends

GAO recommends that FDA collaborate to develop and implement action plans to address the remaining root causes of investigator attrition that balance inspection needs against the need to retain investigators. HHS agreed with this recommendation.

What GAO Found

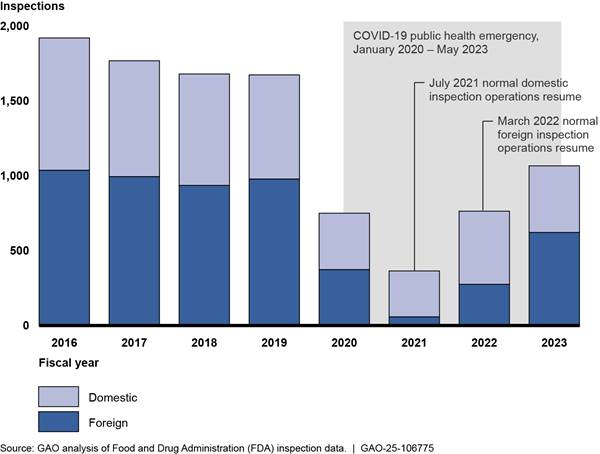

After disruptions during the COVID-19 pandemic in 2020, the Food and Drug Administration (FDA) had largely resumed conducting in-person inspections of foreign and domestic drug manufacturers by March 2022. FDA data show it conducted 621 foreign and 444 domestic inspections in fiscal year 2023, although there were 36 percent fewer than in fiscal year 2019. This decrease was due in part to reduced investigator capacity, according to FDA. As of May 2024, FDA had also progressed with the implementation of two pilot programs intended to address challenges unique to foreign inspections: conducting unannounced inspections and utilizing independent interpreters.

FDA expanded the use of alternative tools to maintain oversight of drug manufacturing during the pandemic. FDA has continued to use one tool—relying on inspection reports from trusted foreign regulators—in lieu of conducting inspections. However, FDA’s use of other tools—remote assessments of information from manufacturers—has declined and will largely be reserved for more targeted use now that inspections have resumed, according to FDA.

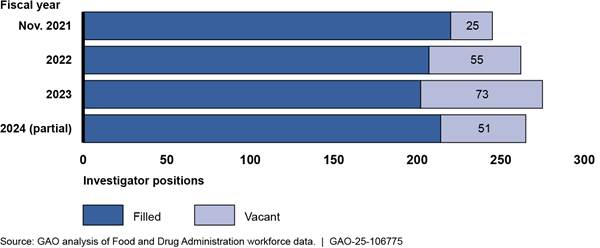

GAO previously reported that as of November 2021, FDA had taken steps to reduce vacancies among its drug inspection workforce. However, since then, investigator attrition has generally outpaced hiring and has resulted in a large number of relatively inexperienced investigators. FDA told GAO this has limited the number of inspections FDA can complete. FDA identified root causes of attrition as the frequency and conditions of travel, pay, insufficient training, heavy workload, and issues of work-life balance. It is implementing action plans to address pay and training. FDA has not yet developed action plans to fully address travel, workload, and work-life balance because potential solutions may not allow FDA to meet its inspection needs. However, the continued loss of experienced investigators is already affecting FDA’s ability to meet inspection goals. Therefore, developing and implementing action plans to address these remaining root causes will help FDA maintain the experienced workforce it needs to oversee global drug manufacturing. This will require continued collaboration with leadership and other stakeholders to identify any actions, resources, or new authorities necessary to implement such plans.

FDA Drug Investigator Vacancies, November 2021–June

2024

|

Abbreviations |

|

|

CDER |

Center for Drug Evaluation and Research |

|

FDA |

Food and Drug Administration |

|

GMP |

Good Manufacturing Practices |

|

HHS |

Department of Health and Human Services |

|

ORA |

Office of Regulatory Affairs |

This is a work of the U.S. government and is not subject to copyright protection in the United States. The published product may be reproduced and distributed in its entirety without further permission from GAO. However, because this work may contain copyrighted images or other material, permission from the copyright holder may be necessary if you wish to reproduce this material separately.

November 13, 2024

The Honorable Bernard Sanders

Chair

The Honorable Bill Cassidy, M.D.

Ranking Member

Committee on Health, Education, Labor and Pensions

United States Senate

The Honorable Cathy McMorris Rodgers

Chair

The Honorable Frank Pallone, Jr.

Ranking Member

Committee on Energy and Commerce

House of Representatives

The Food and Drug Administration (FDA), an agency within the Department of Health and Human Services (HHS), is responsible for ensuring that drugs marketed in the U.S. are safe and effective.[1] Critical to this oversight are its inspections of the establishments manufacturing those drugs. These inspections can identify manufacturing deficiencies, which can lead to serious problems if they are not corrected. For example, in December 2022, FDA began investigating an outbreak of antibiotic-resistant bacterial infections from contaminated eye drops that led to cases of vision loss and death. An FDA inspection of the establishment identified multiple manufacturing deficiencies, including a failure to follow procedures to prevent microbiological contamination.

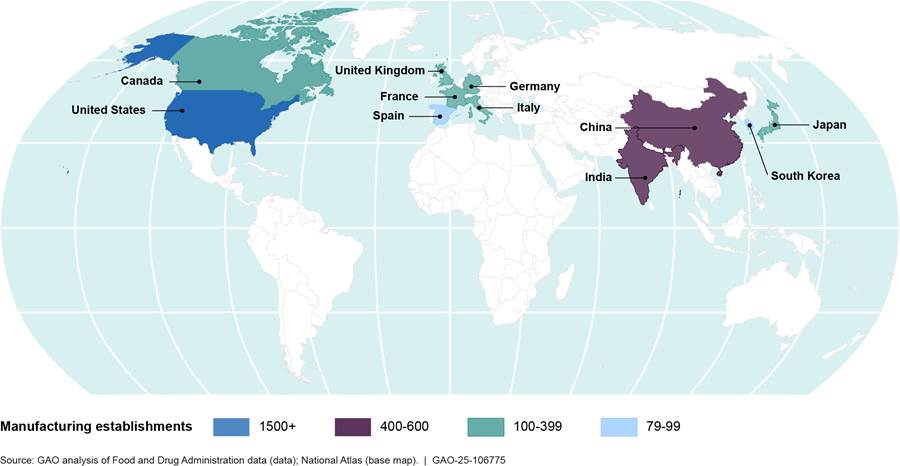

FDA’s inspection responsibilities have been complicated by a manufacturing supply chain that has become increasingly global. As of September 2023, 58 percent of establishments registered with FDA to manufacture drugs for the U.S. market were located overseas.[2] Over many years, FDA has increased the number of inspections it conducted and significantly increased the portion conducted overseas. By 2015, FDA was conducting more inspections in foreign countries than in the U.S.

However, as we previously reported, the COVID-19 pandemic significantly disrupted FDA’s ability to inspect drug manufacturing establishments in person.[3] Beginning in March 2020, FDA largely paused foreign and domestic drug inspections.[4] In response to these disruptions, FDA relied on the use of alternative inspection tools. Such tools included the review of inspection reports from other trusted foreign regulators and the remote assessment of information from manufacturing establishments. While FDA generally had the authority to use these tools prior to the pandemic, it had not used them extensively.

Even before the COVID-19 pandemic disruption, FDA faced challenges in conducting these inspections, which we have reported on extensively and which contribute to the inclusion of FDA’s oversight of medical products in our High-Risk series.[5] One persistent challenge has been vacancies among the investigators who conduct these inspections. Over multiple reports, we have reported on vacancies among FDA’s investigators. In December 2019, we reported that these vacancies contributed to decreased foreign and domestic inspections.[6] In 2022, we reported that FDA had undertaken a number of initiatives to recruit new investigators and had reduced these vacancies, though vacancies still existed among those investigators who specialize in foreign inspections.[7]

The Consolidated Appropriations Act, 2023, includes a provision for us to report on the status of FDA’s foreign drug inspections and its use of alternative tools.[8] In this report, we

1. describe the status of FDA in-person drug inspections,

2. examine FDA inspection workforce vacancies and FDA’s efforts to address them,

3. describe FDA’s use of alternative tools during the COVID-19 pandemic and its plans for the future, and

4.

describe selected foreign regulators’ use of alternative tools to

oversee drug manufacturing establishments in other countries.

For all four objectives, we reviewed relevant federal laws, regulations, or other documentation related to oversight of drug manufacturing establishments. We also interviewed FDA officials from the Center for Drug Evaluation and Research (CDER), which identifies and prioritizes establishments for inspection, the Office of Regulatory Affairs (ORA), which is responsible for conducting the inspections, and the Office of Global Policy and Strategy, which oversees the activities of FDA’s foreign offices. In addition, we interviewed a nongeneralizable selection of 10 current investigators and former investigators who now have other roles at FDA (whom we refer to as “investigators” for the purposes of this report), and who conducted inspections and used alternative tools. We made this nongeneralizable selection to gather the perspectives of staff with a range of experiences with alternative tools, including experiences using more than one tool. The views of these investigators cannot be generalized to other investigators.

To describe the status of FDA in-person drug inspections, we analyzed FDA data on inspections of drug manufacturing establishments.[9] Specifically, we examined FDA data from fiscal year 2019 (the last full year of inspections prior to the start of the COVID-19 pandemic) through fiscal year 2023. Fiscal year 2023 data were the most recent year available when we conducted our analysis. To provide context for the number of inspections, we obtained data from FDA on the number of establishments the agency considered to be subject to inspection in each country as of January 2024, which was the most recently available data at the time of our analysis. Finally, we reviewed agency documents and interviewed agency officials about FDA’s efforts to resume in-person inspections following the COVID-19 pandemic.

To examine vacancies in FDA’s drug investigator workforce and the agency’s efforts to address them, we analyzed FDA data on the number of authorized, filled, vacant, newly hired, and departing investigator positions for fiscal years 2022 through June 30, 2024 (partial fiscal year 2024). Fiscal year 2022 was the first full fiscal year since we last reported on FDA’s efforts to address investigator vacancies; partial fiscal year 2024 was the most recently available data when we conducted our analysis. We also interviewed officials about their efforts to maintain a sufficient pool of drug investigators, and we reviewed FDA documents related to workforce planning and investigator recruitment and hiring. In addition, we interviewed investigators regarding their experiences conducting in-person inspections, including challenges related to inspection staffing. We compared FDA’s efforts and action plans to maintain its drug investigator workforce against selected leading practices for retention previously identified by GAO.[10]

To describe FDA’s use of alternative tools during the COVID-19 pandemic, and its future plans for these tools, we analyzed data from FDA’s Compliance Management System on the agency’s use of alternative tools from fiscal year 2021 (to update our prior analyses of use of such tools in fiscal year 2020) through fiscal year 2023 (the most recent complete year of data available at the time of our analysis). We also reviewed agency documents and interviewed agency officials—including FDA staff involved with setting policy about the past and future use of such tools—and investigators, about their experiences using these tools. Further, we reviewed documents from and interviewed six drug manufacturing industry stakeholder groups about the experiences of their member companies with FDA’s use of alternative tools.[11] These stakeholder groups represent the major components of the drug manufacturing industry: manufacturers of brand-name drugs, generic drugs, active ingredients, over-the-counter drugs, and contract manufacturers. Each of the stakeholder groups represents both member companies with domestic manufacturing establishments and those with foreign manufacturing establishments.

To describe selected foreign regulators’ use of alternative tools to oversee drug manufacturing establishments in other countries, we reviewed documents from and interviewed officials from seven foreign regulators. We selected regulators from Australia, Canada, Japan, New Zealand, Switzerland, the United Kingdom, and the European Union.[12] We selected these seven because they have inspection information sharing agreements with FDA, and they have documented use of alternative tools. We interviewed officials from the seven regulators about the types of alternative inspection tools they use and the challenges and benefits of using such tools.[13]

Our work focused on human drugs regulated by CDER.[14] Further, our work focused on activities related to FDA’s inspections of manufacturing establishments. FDA undertakes other activities to oversee drug quality, such as sampling and testing, which are beyond the scope of our review.[15]

To assess the reliability of the data on inspections, the number of establishments subject to inspection, investigator staffing, and the use of alternative tools, we reviewed related documentation, interviewed knowledgeable agency officials, conducted electronic data testing for missing data and outliers, and compared the data to published information from the same sources, as appropriate. On the basis of these steps, we found these data sufficiently reliable for the purposes of our reporting objectives.

We conducted this performance audit from April 2023 to November 2024 in accordance with generally accepted government auditing standards. Those standards require that we plan and perform the audit to obtain sufficient, appropriate evidence to provide a reasonable basis for our findings and conclusions based on our audit objectives. We believe that the evidence obtained provides a reasonable basis for our findings and conclusions based on our audit objectives.

Background

Globalization of Drug Manufacturing

Drugs sold in the U.S.—including active pharmaceutical ingredients and finished dosage forms—are manufactured throughout the world. These include brand-name, generic, and over-the-counter drugs. As of January 2024, FDA data showed that India and China had the most foreign establishments manufacturing drugs for the U.S. market, with nearly 40 percent of all foreign establishments in these two countries. (See fig. 1.)

Figure 1: Number of Establishments in the U.S. and the 10 Countries with the Most Foreign Drug Establishments Manufacturing Drugs for the U.S. Market, as of January 2024

Note: This figure includes the 10 countries with the most foreign drug

establishments manufacturing drugs for the U.S. market and does not include

those countries with fewer than 79 establishments.

Types of Inspections

Drugs manufactured overseas for the U.S. market must meet the same statutory and regulatory requirements as those manufactured in the U.S. Under its applicable statutory and regulatory authority, FDA’s CDER implements requirements for the safety, quality, effectiveness of, and manufacturing processes for, over-the-counter and prescription drugs. CDER requests that ORA inspect both domestic and foreign establishments to ensure that drugs are produced in conformance with applicable laws of the U.S., including FDA regulations governing current good manufacturing practices (GMP).[16] ORA investigators conduct the inspections.

Investigators generally conduct three main types of

in-person drug manufacturing establishment inspections: preapproval

inspections, surveillance inspections, and for-cause inspections, as described

in

table 1.[17]

|

Type of inspection |

Purpose of inspection |

|

Preapproval inspections |

FDA conducts preapproval inspections before approving a new brand-name or generic drug to be marketed in the U.S. These inspections are designed to verify the accuracy and authenticity of drug application data (such as manufacturing records) to determine that the establishment is following commitments made in the application and to assess whether the establishment can manufacture the product in the application in conformance with applicable regulations to ensure a drug’s identity, strength, quality, and purity.a |

|

Surveillance inspections |

Surveillance inspections are conducted at establishments when drugs are already marketed in the U.S.—either after FDA approval or after marketing for drugs that do not require FDA approval before marketing—and focus on compliance with system-wide controls for ensuring that the manufacturing processes produce high-quality drugs.b Systems examined during these inspections include those related to materials, quality control, production, facilities and equipment, packaging and labeling, and laboratory controls. These systems may be involved in the manufacture of multiple drugs. |

|

For-cause inspections |

For-cause inspections are conducted to investigate specific issues, such as those raised in consumer complaints, reports of product quality issues submitted by consumers or health care professionals, indications of potential manufacturing problems submitted by the manufacturers themselves, or to follow-up on previous FDA regulatory action, among other reasons. |

Source: GAO analysis of Food and Drug Administration (FDA) information. │ GAO‑25‑106775

aWhen FDA receives an application for drug approval (or a supplement to that application related to a manufacturing change), officials review the inspection history of each establishment listed on the application, among other things. According to FDA officials, if an establishment listed on the application has received a satisfactory good manufacturing practices inspection for a similar or more complex product, and the agency has no new concerns, FDA may consider this inspection sufficient and not perform a preapproval inspection of this establishment. FDA may also conduct post-approval inspections that focus on a specific product and are conducted after applications have been approved. Post-approval inspections largely focus on the process validation lifecycle and any manufacturing changes that may have occurred following approval.

bCertain drugs, such as some over-the-counter

drugs, may not require FDA approval before being marketed in the U.S.

While preapproval and for-cause inspections occur in response to specific needs, FDA uses a risk-based process to select establishments for surveillance inspections.[18] CDER first compiles a catalog of the more than 4,000 establishments that are subject to inspection. CDER then applies a risk-based site selection model to the catalog to prioritize establishments for surveillance inspection. Using the results of the model and other information, CDER develops a ranked list of foreign and domestic establishments that FDA considers to be a priority for inspection in a given year and submits that list to ORA. To determine how many inspections to request that ORA conduct in a given year, CDER receives information from ORA on available inspection resources and determines how these resources should be budgeted across multiple inspection programs and other activities, according to FDA officials. Thus, not every establishment will be inspected each year. For example, in fiscal year 2019, there were about 4,200 establishments in FDA’s catalog of establishments subject to inspection and FDA conducted about 1,700 inspections.

FDA Inspection Workforce

FDA has three groups of investigators who conduct domestic and foreign drug manufacturing inspections.

· General pool of investigators. Investigators based in the U.S., who primarily conduct domestic inspections, but who also conduct foreign inspections.

· Dedicated foreign drug cadre. A U.S.-based group of investigators who specialize in foreign inspections.

· Foreign office investigators. Investigators based in FDA’s India or China offices.

We previously identified persistent vacancies among these three groups of investigators. We recommended that FDA develop strategies focused on the recruitment and retention of investigators who specialize in foreign inspections.[19] FDA agreed with our recommendation and in response, in December 2021 FDA formed the GAO Recruitment and Retention Action Plan Work Group, which developed six tailored strategies to recruit, develop, and retain investigators for the foreign drug cadre and the foreign offices.[20] For example, FDA participated in recruiting events and outreach to individuals with interest in or skills relevant to travel, such as former Peace Corps volunteers. FDA also increased the cash incentive for completed foreign trips and launched a three-part training series on foreign travel. As a result of these efforts, we determined that FDA had partially implemented our recommendation. As of July 2024, FDA stated that it planned to form a work group to address recruitment challenges specific to the foreign offices but had not done so. However, FDA stated that ORA and the Office of Global Policy and Strategy continued to work together to address challenges related to the recruitment and retention of foreign office investigators. To fully meet the intent of our recommendation, FDA should detail implementation steps and time frames for its proposed efforts related to foreign office recruitment.

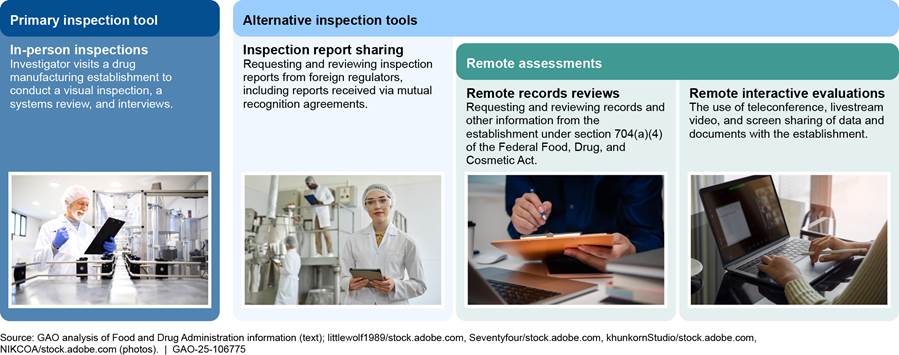

Alternative Tools

While FDA has historically relied on in-person inspections to oversee domestic and foreign establishments, it can also utilize multiple types of alternative tools, in certain circumstances. These generally fall into two categories: review of reports from inspections conducted by foreign regulators, and the remote assessment of information provided by establishments. (See fig. 2.)

Foreign regulator inspection reports. FDA has agreements with regulators

around the world that allow it to share information about drug establishments.

In 2012, federal law authorized FDA to enter into mutual recognition agreements

to recognize inspections conducted by foreign regulators deemed capable of

conducting inspections that meet U.S. requirements.[21] Since then, FDA has entered into

mutual recognition agreements with European regulators to use each other’s

inspection reports, which can reduce duplicative inspections.[22] In contrast, FDA has confidentiality

commitments with certain regulators, which allow FDA to share certain kinds of

inspection information but do not establish that each regulator will recognize

the other’s inspections.

In March 2020, FDA expanded its use of reports obtained through mutual recognition agreements and those obtained through other sharing agreements.[23] First, FDA began recognizing inspections that European regulators conducted outside of Europe, such as in China and India.[24] Second, FDA began expanding use of inspection reports from regulators that are among the members of the Pharmaceutical Inspection Co-operation Scheme, which includes 43 regulators with which FDA shares another agreement and 13 regulators with which FDA does not have an existing agreement, according to FDA.[25] Rather than substituting a report for an FDA inspection, as it can do under mutual recognition agreements, FDA used these reports from other regulators in conjunction with information obtained by FDA through other methods to make oversight decisions.

Remote assessments. FDA may also conduct an examination of an establishment or its records entirely remotely to evaluate compliance with applicable FDA requirements. Remote assessments include the following activities.

· Remote records reviews. In 2012, federal law authorized FDA to request and review records and other information from drug manufacturing establishments subject to inspection.[26] FDA may request records it would typically review during a preapproval or surveillance inspection or may make more targeted requests. Prior to the COVID-19 pandemic, FDA used this authority in a more limited capacity, for example to oversee 10 establishments that the agency would not routinely inspect because of travel warnings.[27]

· Remote interactive evaluations. In April 2021 guidance, FDA described various remote interactive tools the agency may use to conduct an evaluation of an establishment during the COVID-19 public health emergency.[28] Such tools included use of teleconference, livestream video, and screen-sharing of data and documents.

FDA Resumed Inspections Paused during the COVID-19

Pandemic and Progressed with Two In-Person Inspection Pilot Programs

By the start of fiscal year 2023, FDA had resumed conducting in-person inspections paused during the pandemic, but inspection totals remained below pre-pandemic totals due to reduced investigator capacity. As a part of resuming in-person inspections, FDA implemented the unannounced inspections pilot and finalized the design of the independent interpreter pilot.

By Fiscal Year 2023, FDA Had Resumed Inspections Paused during Pandemic Disruptions but Number of Inspections Had Not Returned to Pre-Pandemic Inspection Levels

In fiscal year 2023, FDA conducted more drug inspections than it had since pausing most inspections in March 2020, at the start of the COVID-19 pandemic, but did not reach pre-pandemic inspection totals, according to our analysis of FDA data.[29] (See fig. 3.) These data show FDA conducted 1,065 total inspections in fiscal year 2023, a 40 percent increase from fiscal year 2022. However, this total was 36 percent below the 1,671 inspections conducted in fiscal year 2019, the last full year before the start of the pandemic.

Note: FDA paused all inspections except those deemed mission critical in March 2020 due to the COVID-19 pandemic. The agency resumed normal operations for domestic inspections in July 2021 and began resuming normal operations for foreign inspections in March 2022, according to FDA officials.

The number of inspections FDA conducted was limited by reduced investigator capacity, according to FDA officials. FDA officials told us that they anticipate that fiscal year 2024 inspection totals will be higher than fiscal year 2023 but will remain below pre-pandemic levels due to continued reduced investigator capacity.[30]

As FDA has resumed conducting inspections, surveillance inspections have increased and trends in inspection location and outcomes have become more similar to what FDA conducted prior to the COVID-19 pandemic.

Inspection location. Our analysis of FDA data found that FDA conducted mostly domestic inspections following the start of the pandemic in 2020. However, by fiscal year 2023, 58 percent of drug inspections were of foreign establishments, which was the same as the percent of inspections that were foreign in fiscal year 2019, prior to the pandemic. Similarly, in fiscal year 2023, FDA again conducted the largest number of foreign inspections in India and China, where nearly 40 percent of foreign establishments are located.[31] (See table 2.)

|

Country |

2019 |

2020 |

2021 |

2022 |

2023 |

Number of establishments subject to |

|

India |

305 |

155 |

9 |

83 |

212 |

592 |

|

China |

167 |

30 |

25 |

17 |

90 |

487 |

|

Switzerland |

29 |

10 |

1 |

9 |

37 |

77 |

|

Canada |

70 |

28 |

0 |

30 |

33 |

130 |

|

Japan |

51 |

33 |

8 |

5 |

32 |

124 |

|

Germany |

69 |

12 |

1 |

14 |

20 |

195 |

|

All other foreign countries |

286 |

106 |

15 |

118 |

197 |

1,158 |

|

Foreign (total) |

977 |

374 |

59 |

276 |

621 |

2,763 |

|

Foreign (percent of total inspections) |

58% |

50% |

16% |

36% |

58% |

58% |

|

Domestic (total) |

694 |

376 |

306 |

487 |

444 |

1,980 |

|

Domestic (percent of total inspections) |

42% |

50% |

84% |

64% |

42% |

42% |

|

Total |

1,671 |

750 |

365 |

763 |

1,065 |

4,743 |

Source: GAO analysis of Food and Drug Administration (FDA)

data. | GAO‑25‑106775

Note: Drug manufacturing inspection counts include FDA’s inspections of establishments as part of its drug approval process, to conduct regular surveillance after drugs are marketed in the U.S., and to investigate specific issues. Inspection counts do not include those inspections completed using inspection reports from foreign regulators with which FDA has a mutual recognition agreement. FDA can substitute these reports for its own inspections. Of the countries included in this table, FDA has had a mutual recognition agreement with Germany since 2017 and with Switzerland since 2023.

aJanuary 2024 was the most current data

available on the number of establishments subject to inspection at the time we

conducted our analysis. The number of establishments subject to inspection in a

given country can vary over time. However, the overall trend in the proportion

of foreign to domestic sites has generally remained the same over the past

several fiscal years. (For an analysis of changes in the number of

establishments subject to inspection in the above countries between fiscal year

2019 and 2023, see U.S. Food & Drug Administration, Center for Drug

Evaluation and Research, Fiscal Year 2023 Report on the State of

Pharmaceutical Quality (June 2024).)

|

Surveillance Backlog In 2021, we reported that the postponement of surveillance inspections due to the COVID-19 pandemic created an inspection backlog that could affect the Food and Drug Administration’s (FDA) goal of conducting exclusively risk-driven surveillance inspections. Specifically, as a result of postponements, the number of establishments never inspected or not inspected in the past 5 years increased. This left fewer inspection resources for other establishments identified by FDA’s risk-based site selection model as having the greatest potential for public health risk if the site is out of compliance. We recommended that FDA ensure its future inspection plans analyze and respond to the issues presented by this backlog of surveillance inspections.

FDA agreed with our recommendation and has implemented it. For example, in fiscal year 2024, FDA planned to use abbreviated inspections of certain low risk establishments to increase the total number of surveillance inspections it can complete. As a result, in fiscal year 2024, the proportion of planned surveillance inspections that are of relatively higher risk establishments has increased for the first time since the start of the COVID-19 pandemic, in alignment with FDA’s goal of risk-driven surveillance. However, the backlog caused by postponements continues to be a factor in FDA’s selection of establishments to inspect. Source: GAO review of FDA inspection plans (text); aerogondo/stock.adobe.com (photo). | GAO-25-106775 |

Inspection type. During the COVID-19 pandemic pause in most inspections, FDA considered certain preapproval and for-cause inspections to be mission critical or otherwise of higher priority than routine surveillance inspections.[32] Thus, of the limited number of inspections conducted during fiscal year 2021, the first full fiscal year affected by the pandemic, FDA conducted more for-cause inspections than surveillance inspections. (See sidebar for more details on the postponement of surveillance inspections.) In fiscal years 2022 and 2023, surveillance inspections were the most common type of inspection, according to our analysis.

However, FDA documents and officials note that for-cause inspections will likely continue to exceed pre-pandemic levels. This is due to multiple factors, according to FDA officials. For example, for-cause inspections are necessary to follow-up on compliance actions, such as import alerts, taken as a result of targeted remote records reviews conducted during the pandemic. FDA also noted a general increase in the receipt of information that can trigger a for-cause inspection.

|

Inspection Classifications Based on inspection findings and the Food and Drug Administration’s (FDA) review, each inspection is classified into one of the following categories based on FDA’s determination of whether any deficiencies identified during the inspection are serious enough to warrant regulatory action: No action indicated means that insignificant or no deficiencies were identified during the inspection. Voluntary action indicated means that deficiencies were identified during the inspection, but the agency is not prepared to take regulatory action, so any corrective actions are left to the establishment to take voluntarily. Official action indicated means that serious deficiencies were found that warrant regulatory action. For example, FDA identified possible cross contamination during an inspection, which led to a recall of multiple products.

|

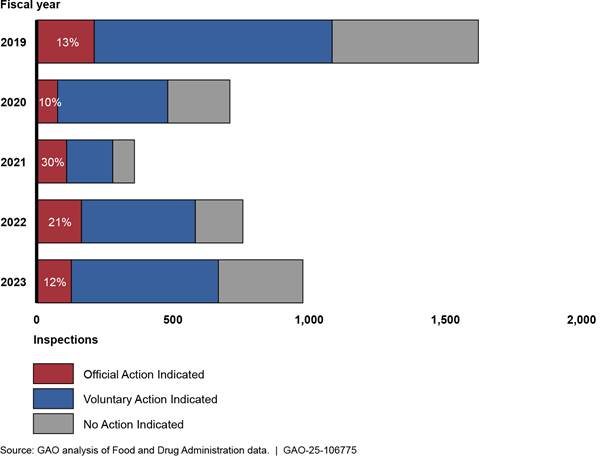

Inspection outcomes. In fiscal years 2021 and 2022, during the COVID-19 pandemic, a higher percentage of inspections FDA conducted received FDA’s most serious classification of official action indicated, as compared to before the pandemic. (See sidebar.) For example, in fiscal year 2021, 30 percent of inspections received an official action indicated classification compared to 13 percent in fiscal year 2019. However, the total number of inspections that received an official action indicated classification did not increase. (See fig. 4.) This higher percentage may reflect the fact that for-cause inspections have increased in recent years, according to FDA documents, which officials noted are more likely to have deficiencies. In fiscal year 2023, as routine surveillance inspections increased, the percentage of inspections classified as official action indicated decreased and was similar to pre-pandemic rates.[33]

Figure 4: Number and

Percentage of FDA Foreign and Domestic Inspection Classifications, Fiscal Years

2019–2023

Note: After each inspection, FDA classifies the inspection into one of three categories based on its determination of whether any deficiencies identified during the inspection are serious enough to warrant regulatory action: No Action Indicated means that insignificant or no deficiencies were identified during the inspection; Voluntary Action Indicated means that deficiencies were identified during the inspection, but the agency is not prepared to take regulatory action, so any corrective actions are left to the establishment to take voluntarily; and Official Action Indicated means that serious deficiencies were found that warrant regulatory action.

Inspection totals do not sum to 100 percent due to

rounding and because some inspections had not yet received a final

classification as of the date that FDA pulled these classification data.

FDA Implemented Its Unannounced Inspections Pilot and Has Finalized the Design of Its Independent Interpreter Pilot

As it resumed inspections paused by the COVID-19 pandemic, FDA implemented one pilot program and finalized the design of another pilot program that are both intended to address unique challenges to conducting foreign inspections. They are (1) the unannounced inspections pilot and (2) the independent interpreter pilot. Historically, foreign inspections were generally preannounced, and investigators generally relied on the establishment being inspected to provide translation services. These unique challenges raised questions about the equivalence of foreign to domestic inspections.[34]

Unannounced inspections pilot. FDA began implementation of this pilot program in March 2022. Consistent with our recommendation, FDA incorporated all five of our leading practices into the pilot’s design and implementation. For example, consistent with leading practices, FDA developed a pilot evaluation plan that outlines an assessment methodology and a plan for collecting both quantitative and qualitative data to assess the effect of conducting unannounced versus preannounced inspections across a range of metrics.[35] Such data include information from FDA data systems on the time and financial resources spent planning and conducting inspections, surveys of investigators that participated in the pilot, and documentation of observations made during the inspections.

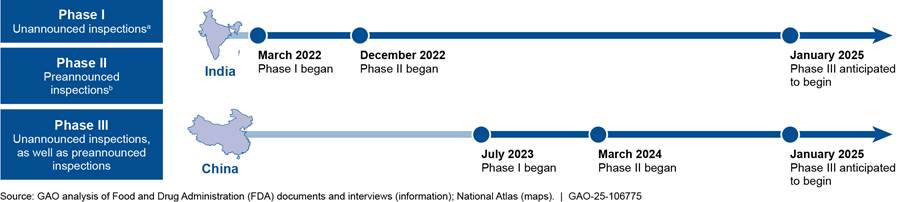

FDA is implementing this pilot in India and China in three phases, as outlined in figure 5.

aUnannounced inspections include those announced on short notice—those in which establishments receive notice of the inspection 72 hours or less before the inspection begins. Establishments may receive much less than 72 hours’ notice, including less than 1 hour.

bPreannounced inspections are announced to the

establishment 8 or more weeks in advance of the inspection.

According to FDA officials, pilot implementation in China was slowed by COVID-19-related travel restrictions, a new visa application process, and new Chinese laws related to espionage and national security. In addition, FDA officials said that increased resource needs for pilot inspections have affected the pace of implementation. Specifically, FDA determined that unannounced inspections in the pilot are to be conducted by two investigators for safety reasons (historically, the majority of inspections were conducted by solo investigators).[36]

As of May 2024, FDA had initiated 114 pilot inspections in India (94 of which were unannounced) and 28 in China (16 of which were unannounced), according to an FDA presentation on the pilot’s status. FDA plans to continue pilot implementation through each phase until it has completed about 250 unannounced and about 250 preannounced inspections in total across both countries.

FDA plans to conduct evaluations at the end of each phase in each country and does not expect to complete the final evaluation until all phases are complete in both countries, which FDA officials anticipate will take several years. FDA completed an internal evaluation of the first phase of the India pilot in April 2023 and gained a number of insights. For example, of the unannounced inspections initiated in India during the first phase of the pilot, FDA noted the following.

· There were two instances in which FDA discovered that a regulatory agency from another country was already on site when FDA arrived at the establishment. According to the evaluation, in these cases FDA and the establishment did not encounter any challenges with this overlap.

· Two inspections could not be completed as planned. Upon initiating the inspection, FDA determined that one establishment was out of business. The second establishment was on import alert and establishment staff told FDA investigators that the establishment was not ready for inspection.[37] In both instances, investigators were re-assigned to an unannounced inspection at another establishment the next day.

According to FDA officials, in both instances FDA learned that these potential challenges could be overcome, and the pilot did not need to be redesigned.

Independent interpreter pilot. Our review of FDA’s April 2023 pilot design document shows that, consistent with our recommendation, FDA incorporated all five leading practices into its design; for example, FDA established two measurable pilot objectives. For the first objective, FDA plans to assess whether the source of an interpreter (either hired by FDA or provided by the inspected establishment) has an effect on an investigator’s ability to conduct a comprehensive and timely inspection. For the second, FDA plans to assess the costs, resources, benefits, and challenges of each interpreter source.

According to pilot design documentation, FDA plans to conduct this pilot in mainland China using interpreters from the State Department. FDA plans to conduct between 34 and 119 inspections as part of the pilot, with the exact number to be determined based on the level of precision desired for the pilot evaluation. Pilot inspections will include preapproval, surveillance, and for-cause inspections to control for variance between inspection types.

FDA reported in May 2024 that implementation of the interpreter pilot was not likely to begin until after fiscal year 2024. FDA reported that it was prioritizing inspection resources for the unannounced inspections pilot and continuing to assess the evolving landscape in China to determine the most appropriate time to launch this pilot. To fully implement our recommendation, FDA needs to provide documentation of pilot implementation.

FDA Is Taking Action to Address Investigator Vacancies but Does Not Have Plans That Address All Root Causes of Attrition

Investigator attrition has led to an increase in drug

investigator vacancies since November 2021. According to FDA, these vacancies,

along with the resulting large number of relatively inexperienced

investigators, has limited the number of drug inspections FDA can complete. FDA

has identified the root causes of investigator attrition and has some

strategies underway to address them, but the agency has not developed action

plans that address all the identified root causes, due in large part to the

fact that implementing such plans would reduce capacity to conduct inspections.

Investigator Attrition Led to Increased Vacancies, Which FDA Says Limited the Number of Inspections Conducted

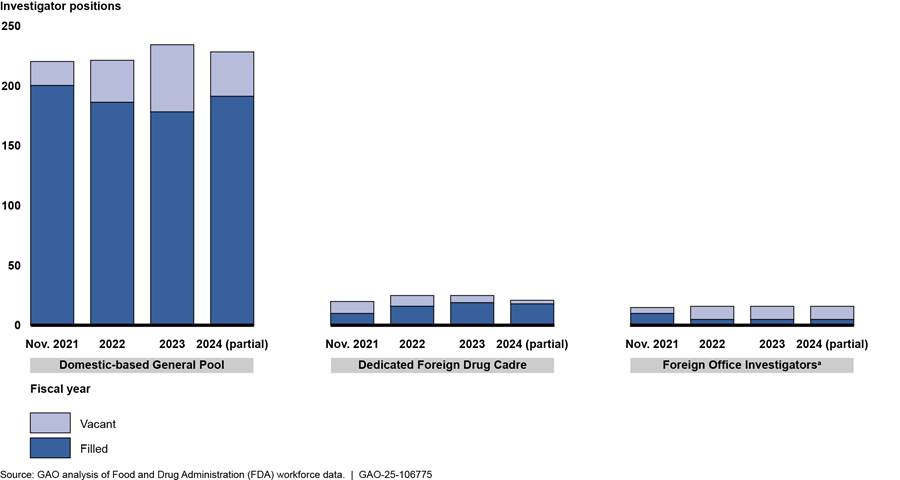

FDA data show the total number of investigator vacancies has increased from 25 vacant positions in November 2021 to 51 as of June 2024.[38] Across the three groups of investigators, the largest increase in vacancies was in the general pool of investigators who conduct both domestic and foreign inspections. However, vacancies also persist in the dedicated foreign drug cadre and among investigators in FDA’s foreign offices. (See sidebar for information on FDA’s three groups of investigators.)

|

Foreign Inspections by Investigator Type The Food and Drug Administration (FDA) relies on a drug inspection workforce primarily composed of three groups of investigators based both in the U.S. and overseas. · General pool of investigators. Investigators based in the U.S., who primarily conduct domestic inspections, but who also conduct foreign inspections. This is the largest group of investigators, and therefore, conduct the majority of foreign inspections. They conducted about 72 percent of all foreign inspections in 2019. · Dedicated foreign drug cadre. A U.S.-based group of investigators who specialize in foreign inspections. They conducted about 18 percent of all foreign inspections in 2019. · Investigators in foreign offices. Investigators based in FDA’s India or China offices. They conducted about 11 percent of all foreign inspections in 2019. All investigators begin their careers in the general pool based in the U.S., conducting only domestic inspections. Investigators may become eligible to conduct foreign inspections, join the cadre, or move to a foreign office after gaining experience and training. Source: GAO review of FDA information. | GAO‑25‑106775 |

General pool of investigators based in the U.S. Most of the current drug investigator vacancies are in the general pool of investigators, which is the largest group of investigators and conducts the majority of domestic and foreign inspections. There are about 230 total authorized investigator positions in this pool. We previously reported that, from December 2019 to November 2021, FDA made progress in hiring for the general pool of investigators.[39] According to FDA, in November 2021, there were 20 vacancies in this pool (a 9 percent vacancy rate).[40] However, as of June 2024, the number of vacancies had increased to 37, a 16 percent vacancy rate. (See fig. 6.)

Note: In our prior report, we counted certain investigator positions as filled for which a new hire had a scheduled start date but had not yet begun work. (See GAO, Drug Safety: FDA Should Take Additional Steps to Improve Its Foreign Inspection Program, GAO‑22‑103611 (Washington, D.C., Jan. 7, 2022).) The data FDA provided for this report, including revised data for November 2021, include only those investigators officially onboard as of that date. Additionally, since our prior report, FDA has determined that certain positions which only occasionally conduct inspections should be excluded from the count of onboard investigators that FDA provided for the previous report.

aThis represents a combined vacancy rate for India and China, the two foreign office locations where FDA has drug investigator positions. Vacancies are greater in China than in India. For example, as of June 2024, four of seven positions in India were vacant, a 57 percent vacancy rate, and seven of nine positions in China were vacant, a 78 percent vacancy rate.

Dedicated foreign drug cadre investigators. FDA recruited more investigators into the dedicated foreign cadre and expanded the number of possible positions, though vacancies remain. As of June 2024, 18 of the 21 cadre positions were filled, compared to 10 of 20 positions as of November 2021.[41] Although FDA has not yet filled every vacancy, according to officials, FDA increased the total number of positions in the cadre because of funding received to conduct inspections under the unannounced inspections pilot, which were expected to largely be conducted by cadre investigators.

Foreign office investigators. Vacancies increased among these investigators, particularly in China.[42] FDA data show that, in November 2021, there was one vacancy among six positions in India and four vacancies among nine positions in China. As of June 2024, four of seven positions in India were vacant and seven of nine positions in China.[43] (See text box for examples of challenges filling positions in China.)

|

Challenges Specific to Filling Positions in FDA’s Foreign Office in China Food and Drug Administration (FDA) officials noted several challenges specific to filling positions in the China office, including restrictions during the COVID-19 pandemic and concerns around the invasiveness of national laws. According to officials, China’s strict zero-COVID policy and related requirements during much of the COVID-19 pandemic resulted in three staff ending their China assignments early. Post-pandemic, officials stated that staff remain concerned about the potential for future lockdowns and raised concerns around the arbitrary enforcement of local and national security laws. For a previous report, officials told us that the challenge of recruiting for positions in China is not unique to FDA, as other agencies with a presence in China also have vacancies. In addition, as of April 2024, the State Department had issued a Level 3 Travel Advisory for China (avoid travel due to serious risks to safety and security). |

Source: GAO analysis of Food and Drug Administration

information. | GAO‑25‑106775

FDA has continued to recruit and hire investigators, but vacancies persist due to challenges with investigator attrition. According to FDA data, from the start of fiscal year 2022 to June 2024, ORA hired 105 new investigators into the general pool of approximately 230 authorized investigators and lost 105. Of these 105 drug investigator losses, 61 percent left for other FDA positions, including other positions in ORA; 29 percent left FDA; and 10 percent retired.[44] The turnover rate for ORA investigators in the general pool was more than twice as high as the ORA-wide turnover rate in fiscal years 2022 and 2023. (See table 3.) As of June 2024, hiring for fiscal year 2024 has been greater than attrition. However, officials noted that they expected additional attrition, as investigator turnover has been an ongoing issue.

|

|

Fiscal year 2022 |

Fiscal year 2023 |

Partial fiscal year 2024 (as of June) |

|

Investigator gains |

35 |

35 |

35 |

|

Attrition |

41a |

40 |

24 |

|

Net change |

-6 |

-5 |

+11 |

|

Turnover rate |

22% |

22% |

13% |

Source: GAO review of Food and Drug Administration (FDA) data. │ GAO‑25‑106775

aThis includes two investigators who accepted

assignments to a foreign office. During the time that investigators from FDA’s

Office of Regulatory Affairs are posted to a foreign office, they are detailed

to the Office of Global Policy and Strategy, a different office within FDA.

High rates of attrition in the general pool of investigators limit FDA’s ability to fill positions in the foreign cadre and the foreign offices, which are filled by more experienced investigators from the general pool.[45] Officials told us that new investigators typically need 2 to 3 years of experience before they can conduct foreign inspections independently, and they must have experience conducting foreign inspections before they are qualified for a position in the foreign cadre or for an assignment as a foreign office investigator. As of June 2024, 36 percent of investigators in the general pool did not have the necessary experience to conduct independent foreign inspections. Officials told us that the limited pool of qualified investigators was one of the top challenges in recruiting investigators to fill foreign office investigator positions.

Investigator attrition has reduced the total number of inspections FDA can conduct, according to FDA documents and officials. Having a less-experienced investigator workforce has also reduced inspection capacity. FDA officials noted that newly hired investigators do not have the same capacity to complete inspections as experienced investigators. In addition, experienced investigators are less efficient in completing inspections because they are training newer staff. According to our review of FDA data and an FDA document, about 63 percent of current investigators were hired within the last 5 years, as of May 2024. Officials stated that, even if the total number of drug investigators currently on board was similar to past years, it is an enormous challenge to maintain a similar number of inspections to previous years with so many inexperienced investigators.

FDA Identified Root Causes of Attrition and Has Taken Some Steps to Address Them but Does Not Have Action Plans for All Causes

ORA, which hires and manages investigators, led FDA efforts to identify the root causes of attrition. ORA is implementing action plans to address some but not all of these root causes. Fully addressing all root causes may require agency-wide collaboration.

FDA identified attrition root causes. Based on our review of ORA documentation and FDA interviews, we found that ORA identified travel, pay, training, workload, and work-life balance concerns as root causes of investigator morale issues leading to attrition. According to officials, ORA initially identified these root causes of attrition through its GAO Recruitment and Retention Action Plan Work Group, which was formed in fiscal year 2022 in response to our prior recommendation.[46] ORA officials stated that they reviewed employee exit surveys and attrition data, as well as data from the annual Federal Employee Viewpoint Survey and employee focus groups.[47] Officials stated that they continue to review these sources on an ongoing basis. Based on their review, officials noted travel and pay as the main causes of attrition. FDA investigators we interviewed also described challenges that align with these root causes.[48]

· Travel. Officials identified travel as the biggest cause of attrition, including both the amount of travel and the conditions of travel. Investigators travel frequently, from 25 to 75 percent of the time according to position descriptions, and may spend long hours in transit, according to officials. Officials provided an example of a trip to China where the investigator left home on Thursday and spent 41 hours in transit to arrive for a Monday inspection.[49] Five investigators we interviewed identified travel as a challenge, including the amount of time away from home and concerns with safety on foreign inspection trips, which are often conducted by a single investigator.[50] One investigator described being assaulted on a foreign trip. Although officials stated foreign travel was the largest concern, they noted that domestic inspections also require a lot of travel and time away from home.

· Pay. According to officials, departing drug investigators often cite better job opportunities, including increased pay, as a reason for leaving the investigator position. FDA workforce data show that the majority of investigators who leave transfer to other positions in FDA where, according to officials, they receive the same or higher pay with less required travel. For example, of those that transferred to other FDA centers from October 2021 through February 2024, at least 29 percent received a salary increase.[51] The average salary increase was 30 percent. However, at least 42 percent of those transferring to other FDA centers accepted a position with an equivalent salary, indicating that increased pay is not always the cause of attrition.

· Training. Ensuring sufficient and standardized training for new investigators was identified as a concern by employee focus group participants and in some exit interviews. For example, focus group participants wanted more hands-on training and tools to standardize the on-the-job training.

· Workload. Officials stated that investigators have a heavy workload during an inspection and a short time frame to complete their inspection reports when they return from a trip. For example, an investigator on a three-week foreign trip covering three different inspections may have their first inspection report due before they return. Four investigators stated that they frequently work overtime during inspections and to complete inspection reports and other tasks.[52]

· Work–life balance. Officials noted that it is difficult for investigators to maintain a work-life balance and make personal commitments, such as being present for child or family events, when they travel so frequently. As a result, officials said investigators take other jobs that are less stressful and require less travel, or that offer remote work options. In FDA exit interviews, departing employees noted that workload expectations made it difficult to have a healthy personal life

and also cited an unreasonable amount of unplanned travel. For example, one investigator noted that investigators may receive a 2-day notice to travel for a domestic inspection.

Changing internal and external factors since the pandemic have further compounded existing issues of travel, workload, and work-life balance. For example, FDA’s increased use of inspection reports from European regulators has reduced the need to conduct inspections in Europe, according to officials. As a result, a larger proportion of foreign trips are to India and China, increasing the total travel time and travel hardship for investigators. Additionally, officials noted that since the pandemic many non-investigator jobs offer telework or remote work opportunities, which may offer better work-life balance.

These root causes of attrition are not always distinct. In particular, issues of travel, workload, and work-life balance are often related and lead to investigator burnout according to officials. For example, some work-life balance issues are the result of travel schedules and workload from internal requirements.

|

Hiring and Pay Flexibilities Most of the Food and Drug Administration’s (FDA) workforce is hired under authority provided by Title 5 of the U.S. Code. The Title 5 hiring process, known as competitive examining, requires agencies to take specific steps related to public notice; screen applications against minimum qualification standards; apply selection priorities such as veterans’ preference; and assess all candidates against job-related criteria. Individuals hired under Title 5 in professional, technical, administrative, and clerical positions typically have their rates of pay assigned under the General Schedule classification system. Hiring flexibilities refer to hiring conducted outside of the competitive examining process, which may include authority under a different title of the U.S. code for the hiring of specific positions or to meet specific or critical needs. Hiring flexibilities may allow agencies to simplify the hiring process. The 21st Century Cures Act provided FDA with special pay authorities that provide for greater flexibility in setting pay, such as through the establishment of alternative pay bands with a higher maximum annual pay than is available under the General Schedule. Under this authority, FDA may convert or reappoint qualified existing staff to these alternative pay bands. Source: GAO review of

federal hiring authorities. | |

Action plans implemented. ORA has developed and is implementing action plans addressing the root causes of pay and training. According to ORA officials, they prioritized these as they were within ORA’s control and could be addressed using existing human capital guidance and flexibilities.

· Pay. ORA is expanding the use of Title 21 hiring authorities to include all investigators, which allows them to offer a higher maximum salary than is available under the traditional General Schedule pay system.[53] (See sidebar and table 4.) The use of Title 21 hiring and pay authorities was previously focused on certain FDA centers (such as CDER) and positions that support the development, review, and regulation of medical products. As a result, some investigators previously left ORA to take a Title 21 position at an FDA center, according to FDA salary data and officials. ORA began its expansion of Title 21 hiring authorities in fiscal year 2022 by converting certain investigator positions at particular risk of attrition to Title 21 positions, starting with the foreign cadre positions. In fiscal year 2024, ORA began hiring most new investigators under Title 21, according to officials, and will next focus on converting existing investigators to Title 21, according to an agency document.[54]

Table 4: Examples of Higher Maximum Pay Ranges for FDA Drug Investigators under Title 21 Pay Bands Compared to the General Schedule Pay Scale for the Washington, D.C., Region, as of January 2024

|

Type of staff and pay bands |

Minimum annual pay |

Maximum annual pay |

|

Associate Investigators |

|

|

|

General Schedule (GS-7)a |

$55,924 |

$72,703 |

|

Title 21 (pay band W)b |

$55,924 |

$74,155 |

|

Investigators I and II |

|

|

|

General Schedule (GS- 9-11) |

$68,405 |

$107,590 |

|

Title 21 (pay bands Y or A) |

$68,405 |

$109,506 |

|

Senior Investigators I |

|

|

|

General Schedule (GS-12) |

$99,200 |

$128,956 |

|

Title 21 (pay band B) |

$99,200 |

$133,845 |

|

Senior Investigators IIc |

|

|

|

General Schedule (GS-13) |

$117,962 |

$153,354 |

|

Title 21 (pay band C) |

$117,962 |

$164,260 |

|

Senior Investigators III |

|

|

|

General Schedule (GS-14) |

$139,395 |

$181,216 |

|

Title 21 (pay band D) |

$139,395 |

$191,900 |

Source: GAO analysis of documentation from Food and Drug Administration (FDA) and from the Office of Personnel Management. | GAO‑25‑106775

a5 U.S.C. ch. 31, subch. I. The General Schedule pay system typically applies to those hired under Title 5 of the U.S. code.

b21 U.S.C. 379d-3a. Hiring authority under Title 21 was originally provided by the 21st Century Cures Act. Pub. L. No. 114-255, 3072(a), 130 Stat. 1033, 1134 (2016). The Food and Drug Omnibus Reform Act of 2022 expanded this authority to apply to more positions and offices within FDA. Pub. L. No. 117-328, 3624, 136 Stat. 5807, 5879.

cAccording to an FDA document, external applicants are eligible for Investigator I and II and Senior Investigator I positions, depending on education and experience. Senior Investigator II positions and higher require existing FDA experience.

· Training. ORA expanded on-the-job training opportunities in February 2022 to include voluntary early participation in foreign inspections along with a senior investigator and also created working groups to oversee training proposals. ORA’s annual operational plans continue to include various training improvements, standardization efforts, and evaluations.[55] These efforts are intended to ensure newly hired investigators can independently conduct domestic inspections within 18 months and ensure current staff stay informed on industry and technology changes, according to ORA’s operational plans.

Unaddressed root causes. ORA, and FDA overall, have not implemented action plans to fully address three root causes of investigator attrition the agency has identified: travel, workload, and concerns with work-life balance. Leading practices for employee retention identified by GAO state that agencies should determine root causes of employee morale problems that lead to attrition and take action to address them by developing and implementing action plans linked to root causes.[56] According to the Office of Personnel Management, developing a workforce action plan involves the identification of strategies, plans to implement these strategies, and measures for assessing progress.[57] Furthermore, the Office of Personnel Management’s steps for action planning state that agencies should identify the necessary budget, resources, staff, and approvals needed to take action.

According to ORA officials, they have discussed options that may help address the amount of travel, investigator workload, and work-life balance issues, but they have not developed action plans because implementing such plans would reduce ORA’s current capacity to conduct inspections. ORA would thus not meet inspection goals set by CDER. For example, ORA discussed options to temporarily move some investigators to other positions that do not require travel or reduce the total number of weeks of foreign travel investigators are expected to complete in a year. However, ORA has not gone beyond dialogue to develop action plans. This is because of the potential effect on current inspection capacity that would be caused by reducing the number of inspections or weeks of foreign travel conducted by individual investigators.

For certain travel and workload concerns, ORA has worked with other FDA stakeholders and identified potential strategies to help address the concern without reducing inspection capacity. However, such strategies will not fully address the issues underlying these root causes, such as the amount of travel. For example, according to agency documents and officials, ORA is considering strategies to improve the travel planning process, which could reduce investigators’ travel stress and discomfort.[58] However, this would not affect the amount of travel required and its effect on work-life balance. Additionally, these potential strategies are still in development and thus lack action plans for implementation.

Leadership in ORA, CDER, and FDA more broadly is also collaborating to identify strategies to help meet inspection goals and improve overall inspection capacity, though these efforts do not address the root causes leading to investigator burnout and attrition. For example, according to an agency document, ORA and CDER are implementing a multi-year plan for CDER to conduct certain preapproval inspections instead of ORA, which could reduce the total burden of inspections on ORA. However, according to ORA officials, this would not result in reduced inspections and travel for individual investigators. Investigators would still be conducting the same number of inspections (and inspection-related travel) to meet other inspection goals, such as for surveillance inspections.

Given the need to balance current inspectional needs against the need to retain an experienced workforce, developing action plans to address attrition will likely require ORA, CDER, and other relevant stakeholders to continue to collaborate to identify strategies that appropriately balance these priorities. To successfully develop action plans that address the remaining root causes of attrition, FDA will need to identify the actions, resources, and any new authorities necessary to implement them. This will require an agency-wide effort with additional FDA stakeholders beyond ORA and CDER if implementing action plans requires changes to regulations or to current FDA or HHS policy or additional resources beyond what is currently available to ORA. For example, ORA officials stated that increasing the number of investigators could help meet inspection goals in the future, but ORA would need time and additional senior investigators in order to train them. According to officials, additional funding and resources to support training while ORA rebuilds its inspection workforce could help alleviate pressure on the current senior investigators, who are also needed to conduct inspections. However, officials told us that FDA does not have the resources to provide additional training resources.

While we recognize that addressing these travel, workload, and work-life balance issues could affect ORA’s ability to meet inspection goals, the continued loss of experienced investigators is already having this effect. Developing and implementing action plans can help FDA reduce investigator turnover and maintain an experienced investigator workforce. Continued collaboration between ORA, CDER, and other stakeholders in developing these action plans will help ensure that FDA identifies strategies that balance current inspectional needs against the need to retain an experienced workforce, as well as any actions, resources, or new authorities necessary to implement them. Lack of an experienced workforce increases the burden on senior investigators and further reduces FDA’s inspection resources, making it unable to fully meet its mission to oversee the global drug manufacturing supply chain.

FDA Used Certain Alternative Tools Extensively during the COVID-19 Pandemic and Plans Some Continued Use to Supplement In-Person Inspections

FDA used three types of alternative inspection tools

during the COVID-19 pandemic. During the pandemic, FDA expanded its use of

inspection reports from foreign regulators. The agency also used remote records

reviews extensively but used remote interactive evaluations relatively rarely.

Going forward, FDA plans to continue to use all three alternative tools, when

warranted, to supplement in-person inspections.

FDA Increased Use of Inspection Reports from Foreign Regulators during the COVID-19 Pandemic

|

Inspection Report Sharing

This means requesting and reviewing inspection reports from foreign regulators, including reports received via mutual recognition agreement. Source: GAO analysis of Food and Drug Administration information (text); Seventyfour/stock.adobe.com (photo). | GAO‑25‑106775 |

From fiscal years 2020 through 2023, FDA increased its use of inspection reports from European regulators with which FDA has a mutual recognition agreement in lieu of routine surveillance inspections of establishments manufacturing drugs already marketed in the U.S.[59] In fiscal year 2019, FDA substituted reports from inspections that European regulators conducted within their own country for about 100 FDA inspections. In the first year of the pandemic, fiscal year 2020, FDA substituted such inspection reports for over 160 FDA inspections. That total reduced in fiscal years 2021 and 2022 due to a decrease in inspection activity among all regulators, according to FDA officials.[60] However, when travel restrictions eased and European regulator domestic inspections rebounded in fiscal year 2023, FDA substituted almost 200 such reports for its own inspections.

FDA also used the added availability of reports of inspections conducted by certain European regulators in other countries during this period, although FDA decreased its use of them over time. Specifically, FDA substituted reports of inspections conducted by European regulators in other countries, such as India and China, for FDA inspections about 30 times in fiscal year 2021, but this decreased to less than five times in fiscal year 2023. FDA indicated this decrease was because European regulators had reduced their foreign inspection travel during that time and there were fewer inspection reports available.

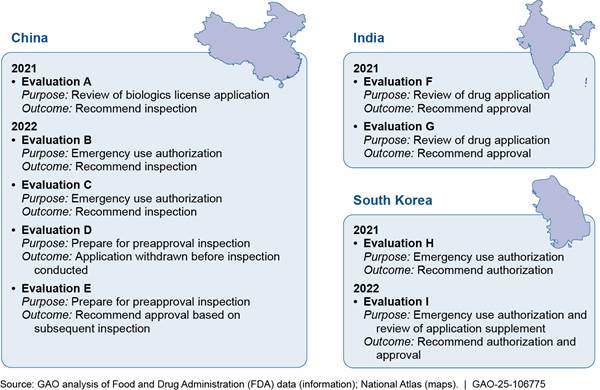

FDA also used foreign regulator inspection reports to support the review of applications for new drugs or for marketed drugs with manufacturing changes. FDA used information from foreign regulators for review of drug applications over 120 times from fiscal year 2021 through fiscal year 2023.[61] During this time period, FDA reviewed European regulator inspection reports for this purpose over 100 times, while they reviewed inspection reports from other foreign regulators less than 20 times. FDA officials explained that using inspection information from regulators with whom FDA does not have a mutual recognition agreement is resource intensive, because each report is assessed on a case-by-case basis. For example, FDA once received an inspection report from a regulator that was three pages long with few details, which was insufficient for FDA’s needs.

Although FDA has increased its use of inspection reports from European regulators with which it has a mutual recognition agreement, the agency still may need to conduct its own inspections in their countries. For example, according to FDA officials FDA may determine an inspection report from a European regulator is not applicable if the scope of the inspection was different, or if FDA identifies risks that require an in-person inspection. FDA may also determine, on a case-by-case basis, that due to extenuating circumstances, certain inspections should be conducted by FDA, such as those initiated by information received from a confidential informant, or with a high likelihood of litigation. In addition, FDA officials explained that FDA regulates some products as drugs, such as sunscreens containing SPF and anti-cavity toothpaste, whereas they are regulated as cosmetics by European regulators. In the absence of an applicable report or other inspection results, FDA may request that the European regulator conduct an inspection on FDA’s behalf; however, this is dependent on the other regulator’s inspection capacity. FDA officials explained that a portion of these requests may remain unfulfilled by the time needed, in which case FDA must perform the inspection.

FDA Used Remote Records Reviews Extensively during the COVID-19 Pandemic and Changed Its Policies and Practices as the Pandemic Progressed

FDA used remote records reviews for two main purposes from fiscal year 2021 through 2023: 1) to gather information that would normally be obtained during an inspection and 2) to provide more targeted oversight of manufacturing establishments.

|

Remote Records Reviews

These include requesting and reviewing records and other information from the establishment under section 704(a)(4) of the Federal Food, Drug, and Cosmetic Act. Source: GAO analysis of Food and Drug Administration information (text); khunkornStudio/stock.adobe.com (photo). | GAO‑25‑106775 |

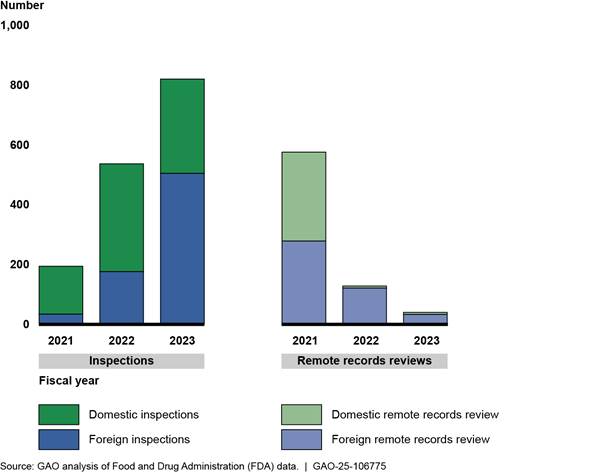

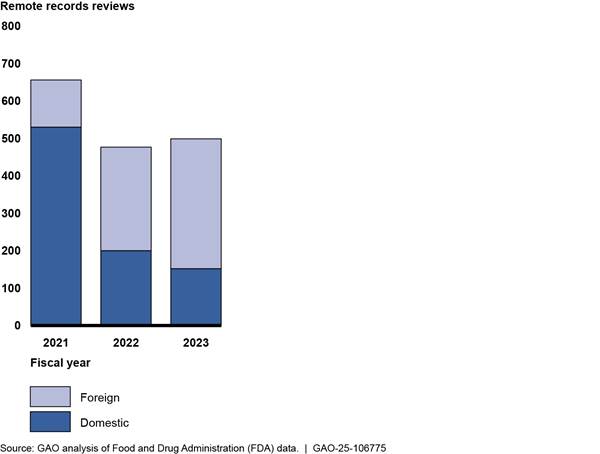

Gathering information normally collected during an inspection. While not equivalent to an inspection, FDA used these reviews to gather information it could use to inform decisions about drug approval or the scope of future surveillance inspections. Early in the COVID-19 pandemic, FDA used remote records reviews extensively in this way, with nearly 600 reviews in fiscal year 2021. (We previously reported that, prior to the COVID-19 pandemic, FDA used remote records reviews in a more limited capacity. Specifically, FDA used this tool to obtain information from 10 establishments that the agency would not routinely inspect because of travel warnings.[62]) However, this use of remote records reviews declined as FDA returned to routine domestic inspections in July 2021 and then later returned to routine foreign inspections in March 2022 everywhere except China. (See fig. 7.) The remote records reviews FDA conducted in fiscal year 2021 were nearly evenly split between foreign and domestic establishments. However, for fiscal years 2022 and 2023, more than two-thirds of FDA’s remote records reviews were related to foreign establishments—most frequently to those located in China and India.

Figure 7: FDA Inspections and Remote Records Reviews Used to Support Drug Application Review or Surveillance of Manufacturing Establishments, by Location, Fiscal Years 2021–2023

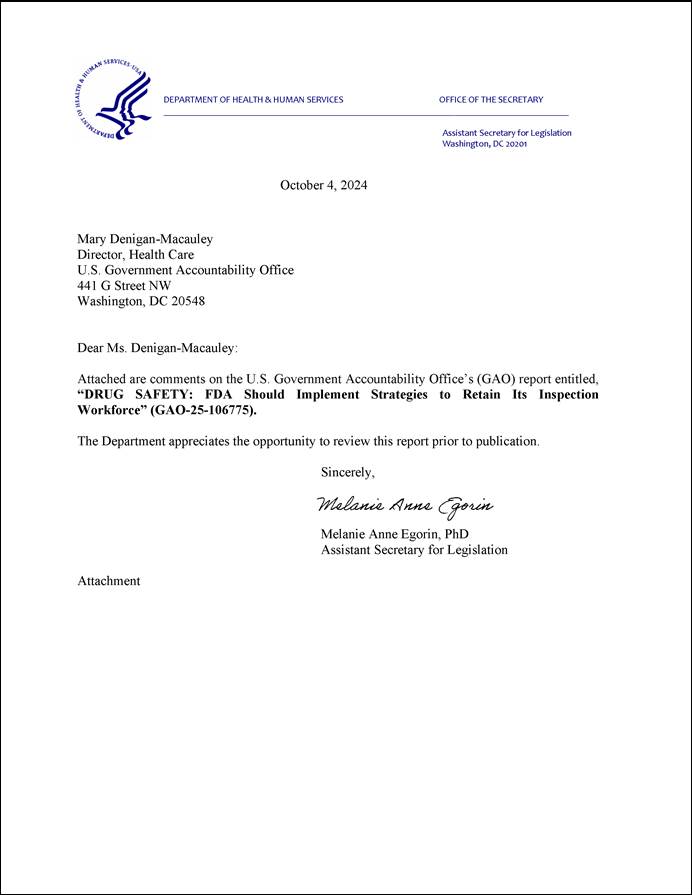

Providing more targeted oversight of manufacturing establishments. From fiscal years 2021 through 2023, FDA also used remote records reviews to request records and other information from establishments for more targeted reasons, as outlined below. The use of targeted remote records reviews remained relatively high across these three fiscal years, even after inspections resumed (see fig. 8).

Figure 8: FDA Remote Review of

Drug Manufacturing Establishment Records for a Targeted Reason, by Location,

Fiscal Years 2021–2023

According to FDA officials, the agency conducted targeted reviews for the following reasons.

· Triaging for potential inspections. According to officials, FDA used these reviews to determine whether an establishment was subject to an inspection before sending out investigators. Officials told us that FDA requested records from foreign and domestic establishments that had not previously received a human drug surveillance inspection.[63]

· Preparing for planned inspections. FDA officials told us that using these reviews in advance of a planned inspection can allow investigators to identify and focus on areas of concern during the subsequent inspection. FDA requested records from about 50 foreign and domestic establishments for this purpose.

· Investigating potential compliance issues. According to officials, FDA used these reviews to evaluate establishments’ compliance and take regulatory action as appropriate. This allowed the agency to help stop potentially contaminated drugs from entering the U.S. supply chain without conducting inspections. Based on these reviews, FDA issued warning letters and placed manufacturers on import alert based on their failure to respond to FDA’s request for records or based on inadequate responses.[64] (See table 5.)

Table 5: Examples of FDA’s Use of Remote Records Reviews to Investigate Potential Compliance Issues at Drug Manufacturing Establishments, Fiscal Years 2021–2023

|

Drug |

Potential compliance issue |

Use of remote records reviews |

|

Hand sanitizer |

In 2020, FDA identified a sharp increase in hand sanitizer products that were labeled to contain ethanol but tested positive for contamination with substances like methanol. Methanol can be toxic when absorbed through the skin and can be life-threatening when ingested. |

FDA issued about 700 records requests to hand sanitizer manufacturers to assess whether drug manufacturers were conducting required testing for contaminants and were in compliance with relevant FDA guidance. |

|

Oral liquid drugs, such as cough, allergy, and pain relief medications |

In 2022 and 2023, oral liquid drugs contaminated with diethylene glycol or ethylene glycol were associated with more than 300 deaths outside of the U.S., primarily among children under the age of 5. |

FDA issued about 170 records requests to assess whether drug manufacturers were conducting required testing to detect and prevent diethylene glycol contamination. |

|

Non-application sterile drugs, including eye drops and ointments |

In 2023, FDA identified contaminated over-the-counter eye drops that led to infections, partial loss of vision, and blindness. |

FDA issued two requests to drug manufacturers that had never been inspected to assess manufacturer controls to ensure product sterility and preservative formulations, according to FDA officials.a |

Source: GAO analysis of Food and Drug Administration (FDA) information. | GAO‑25‑106775

Note: Based on the failure of manufacturing establishments to respond to FDA’s requests for records or based on inadequate responses, FDA issued warning letters (which notify establishments that FDA may take enforcement action if violations are not promptly and adequately corrected) and placed manufacturers on import alert (which inform FDA staff that the agency has enough evidence to detain an establishment’s products that have been offered for entry into the U.S.)

aSome over-the-counter drug manufacturers can

legally market their products in the U.S. before FDA has conducted an

inspection to verify compliance with manufacturing requirements. In addition to

these two remote records reviews, FDA also conducted in-person inspections of

other manufacturers of these non-application sterile drugs, according to FDA

officials.

Over the course of the COVID-19 pandemic, FDA changed its remote records reviews’ policies and practices. These changes were in areas where industry stakeholders noted concerns about their experiences with remote records reviews, as outlined below.