F-35 JOINT STRIKE FIGHTER

Actions Needed to Address Late Deliveries and Improve Future Development

Report to Congressional Committees

United States Government Accountability Office

A report to congressional committees

For more information, contact: Jon Ludwigson at ludwigsonj@gao.gov.

What GAO Found

After years of cost growth and schedule delays in its hardware and software modernization effort for the F-35 aircraft, known as Block 4, the Department of Defense (DOD) is in the process of establishing a new major subprogram to help meet cost, schedule, and performance goals. Currently, Block 4 costs are over $6 billion more and completion is at least 5 years later than original estimates. The program plans to reduce the scope of Block 4 to deliver capabilities to the warfighter at a more predictable pace than in the past.

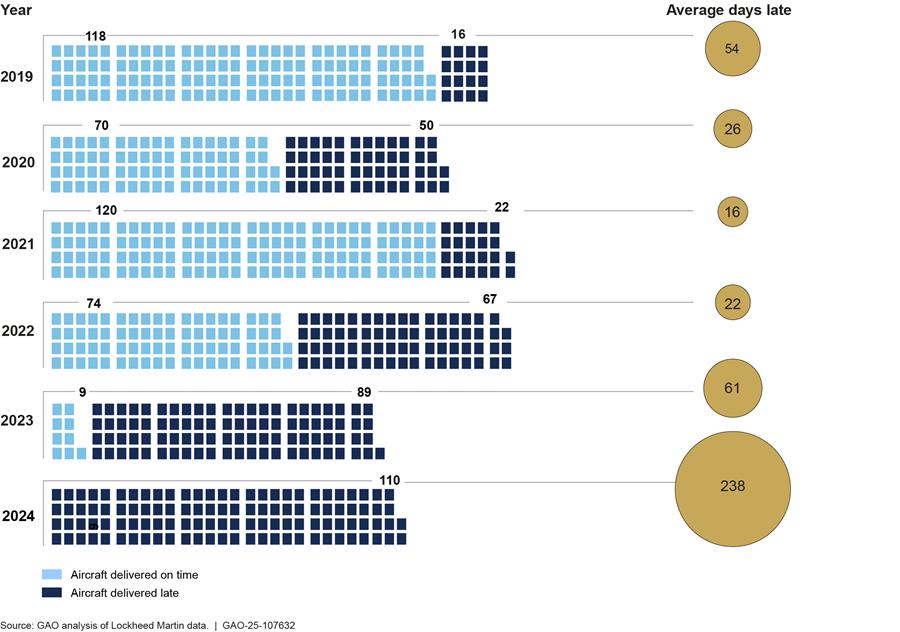

Contractors for the program, Lockheed Martin and Pratt & Whitney, continued delivering aircraft and engines late. For instance, in 2024, Lockheed delivered 110 aircraft. All were late by an average of 238 days, up from 61 days in 2023.

Lockheed Martin’s Technology Refresh 3 (TR-3)—a $1.9-billion suite of hardware and software upgrades that are critical to the Block 4 modernization effort—was the primary driver of late aircraft deliveries in 2024. Evaluating Lockheed Martin’s capacity to deliver aircraft on time would help determine how many aircraft the program should plan to purchase.

In recent years, the program paid contractors, such as Lockheed Martin, hundreds of millions of dollars in incentive fees that were intended to improve on-time delivery. However, the structure of on-time delivery incentives allowed the contractor to deliver aircraft up to 60 days late and still earn some of the fee. To avoid rewarding late deliveries, the program should reevaluate its use of fees in future contracts and better align them to achieve desired production outcomes.

As it stands up new modernization subprograms, the F-35 program has opportunities to deliver capabilities faster. GAO’s work on leading practices for product development has found that leading companies employ an iterative process of design, validation, and production to quickly develop and deliver products. While the program is implementing some aspects of these practices, it would benefit from expanding the use of modern design tools, such as digital models that developers can test in a simulated environment, to more rapidly deliver capabilities to the warfighter than it has historically.

Why GAO Did This Study

The F-35 Joint Strike Fighter plays a crucial role in national security for the U.S. and its partners and allies. The aircraft’s unique stealth technology and advanced sensor networking systems provide critical capabilities to DOD’s tactical air portfolio. DOD estimates that Block 4 and engine and power thermal management modernization—as well as the costs to maintain and operate the 2,470 planned aircraft over the 77-year life cycle—will exceed $2 trillion.

Congress included a provision in statute for GAO to review the F-35 program. This report assesses, among other things, (1) DOD’s progress in Block 4 modernization efforts; (2) the extent to which contractors delivered F-35 engines and aircraft within contract time frames and earned related incentives; and (3) the program’s use of leading practices for product development.

GAO conducted site visits to contractor facilities; collected and analyzed cost, schedule, and production data; reviewed relevant program documentation; and interviewed DOD officials and contractor representatives.

What GAO Recommends

GAO is making six recommendations to DOD, including that it evaluates Lockheed Martin’s capacity to meet planned deliveries on time; reevaluates the use of incentive fees to better achieve the desired schedule; and expands and formalizes the use of leading practices for product development. DOD concurred with four recommendations and partially concurred with two. For all six recommendations, DOD cited actions it is taking to address them. GAO acknowledges DOD has taken some positive steps and believes further action is warranted to fully address the recommendations, as discussed in the report.

Abbreviations

This is a work of the U.S. government and is not subject to copyright protection in the United States. The published product may be reproduced and distributed in its entirety without further permission from GAO. However, because this work may contain copyrighted images or other material, permission from the copyright holder may be necessary if you wish to reproduce this material separately.

|

DOD |

Department of Defense |

|

EPM |

engine and power thermal management modernization |

|

LRIP |

low-rate initial production |

|

MVR |

major variance request |

|

NDAA |

National Defense Authorization Act |

|

PTMU |

power thermal management upgrade |

|

TR-3 |

Technology Refresh 3 |

This is a work of the U.S. government and is not subject to copyright protection in the United States. The published product may be reproduced and distributed in its entirety without further permission from GAO. However, because this work may contain copyrighted images or other material, permission from the copyright holder may be necessary if you wish to reproduce this material separately.

September 3, 2025

Congressional Committees

The Department of Defense (DOD) is currently fielding and modernizing the F-35 Joint Strike Fighter, a family of fifth-generation strike fighter aircraft that integrates low-observable (stealth) technology with advanced sensors and computer networking capabilities. DOD uses the F-35 to perform a wide range of missions and it is vital to the success of U.S. combat operations and homeland defense. DOD aims to procure 2,470 F-35s to replace several other aircraft used by the Air Force, Navy, and Marine Corps. DOD completed the final phase of the original F-35 development program in March 2024, which was over a decade delayed and cost $250 billion more to acquire than the original estimates. Since it started production in 2006, the program has delivered over 1,100 aircraft to the U.S. military departments, international partners, and foreign military sales customers.[1]

The program is upgrading the capabilities of the aircraft and its systems to meet evolving warfighter needs and implement technology innovations. For several years, the program has focused on the Block 4 modernization—the effort to deliver upgraded capabilities. To fully enable many Block 4 capabilities, the program is working to finish development and delivery of Technology Refresh 3 (TR-3), a suite of upgraded hardware and software. Since 2021, we have reported on DOD’s challenges to completing TR-3 development. As a result of these challenges, the program has delivered aircraft late and delayed fielding new capabilities.[2] The program is also taking steps toward modernizing the F-35 engine and related subsystems to provide additional power and cooling that post–Block 4 capabilities will need.

In 2024, Congress directed DOD to manage all Block 4 and TR-3 elements collectively as a major subprogram. Major subprograms have separate cost, schedule, and performance metrics from the broader F-35 aircraft acquisition program.[3]

Since 2001, we have examined various aspects of the F-35 program and have made 53 recommendations to improve the program. As of July 2025, DOD has taken action to address more than half of our recommendations, leading to improvements such as increased focus on reliability and maintainability efforts. Fully implementing the open recommendations could help further improve F-35 program outcomes.

The National Defense Authorization Act (NDAA) for Fiscal Year 2020 includes a provision for us to review the F-35 program’s manufacturing improvements, Block 4 progress, and other issues.[4] In this report, we assess (1) DOD’s progress with its Block 4 modernization efforts, (2) the extent to which contractors delivered F-35 engines and aircraft within contract time frames and specifications, (3) DOD’s progress in establishing a major subprogram to modernize the F-35 engine and related subsystems, and (4) the F-35 program’s use of leading practices for product development.

To address our objectives, we:

· conducted site visits and interviewed officials and representatives from the F-35 joint program office, Lockheed Martin (prime aircraft contractor), Pratt & Whitney (prime engine contractor), and the Defense Contract Management Agency, which administers contracts for DOD;

· assessed program documentation, including cost and schedule estimates, for Block 4 modernization and risk mitigation plans for TR-3 hardware and software delays;

· analyzed contracts, cost, schedule, and production data, such as on-time deliveries, requests to deviate from the contract, and performance incentive fees;

· reviewed documentation related to engine and power thermal management systems modernization efforts, such as contracts and preliminary schedules; and

· evaluated the program’s responses to a questionnaire related to the program’s implementation of our leading practices for product development.[5]

For each objective, we corroborated the data we collected from program officials and contractor representatives with other data sources or knowledgeable officials, or attributed the data as appropriate. We determined that all the data we used were sufficiently reliable for the purposes of our reporting objectives. See appendix I for a detailed description of our objectives, scope, and methodology.

We conducted this performance audit from June 2024 to September 2025 in accordance with generally accepted government auditing standards. Those standards require that we plan and perform the audit to obtain sufficient, appropriate evidence to provide a reasonable basis for our findings and conclusions based on our audit objectives. We believe that the evidence obtained provides a reasonable basis for our findings and conclusions based on our audit objectives.

Background

F-35 Program Cost Increases

Since establishing its baseline cost estimate of $233 billion in 2001, DOD has significantly revised the cost and schedule estimates for the F-35 program several times, and costs continue to rise.[6] For example, DOD revised this estimate in March 2012 after the unit cost of each aircraft grew by an amount that exceeded critical thresholds established by statute—a condition known as a Nunn-McCurdy breach.[7] The revised 2012 estimate totaled nearly $396 billion, a $163 billion increase. In our prior work, we identified the lack of adequate knowledge and high levels of concurrency as the major drivers of the significant cost and schedule growth and other performance shortfalls witnessed by the program.[8] Since 2012, the program has revised its baseline schedule four more times due to delays in development and rising costs, among other things.

The program has not recently reported updated cost estimates, but the most recent data reflect higher than expected costs. According to the December 2023 Modernized Selected Acquisition Report (the most recent available DOD cost estimate), total acquisition costs have increased to $485 billion. This is an increase of $43 billion from the previous December 2022 estimate and $89.5 billion more than the March 2012 baseline estimate. According to program officials, the recent cost increases are largely attributable to an increase in scope in the Block 4 modernization effort and TR-3 cost increases (see table 1).

Table 1: Current F-35 Acquisition Costs Are $89.5 Billion More Than 2012 Baseline Estimate (dollars in billions)

|

Cost category |

October 2001 baseline |

March |

December 2022 estimate |

December 2023 estimate |

Difference from 2012 to 2023 |

|

Development |

34.4 |

55.2 |

79.8 |

87.4 |

32.2 |

|

Procurement |

196.6 |

335.7 |

358.5 |

393.8 |

58.1 |

|

Military construction |

2.0 |

4.8 |

4.0 |

4.0 |

(0.8) |

|

Total program acquisition |

233.0 |

395.7 |

442.3 |

485.2 |

89.5 |

Source: GAO analysis of Department of Defense data. | GAO‑25‑107632

Note: Costs in the table are in then-year dollars in billions and reflect the most recent data from the December 2023 Modernized Selected Acquisition Report. Differences may occur due to rounding.

In addition, the program office estimates that the costs to operate and sustain the F-35 fleet through its 77-year life cycle are at least $1.58 trillion, bringing the F-35 program’s total acquisition and sustainment costs to over $2 trillion.[9] We have reported on sustainment cost growth for years, most recently in 2024.[10]

F-35 Modernization Efforts

Current F-35 modernization efforts include upgrades to Block 4 and TR-3 hardware and software and the engine and power thermal management subsystems.

Block 4. DOD is now in the seventh year of its $16.5 billion capability modernization effort to upgrade the F-35’s hardware and software. Block 4 intends to produce many new capabilities for the aircraft, enabled by these upgrades. Examples of these capabilities include new weapons, radar enhancements, and technology to avoid aircraft collisions. DOD intends for Block 4 to help the aircraft address new threats that have emerged since DOD established the aircraft’s original requirements in 2000.

In May 2023, we reported that the Block 4 program was experiencing developmental delays and cost increases. We recommended that the program improve its reporting on Block 4 cost growth.[11] DOD concurred with the recommendation but has not updated its Block 4 cost estimate since 2021. In May 2024, we reported that the program was establishing this effort as a subprogram, which will have its own cost, schedule, and performance baseline.[12]

TR-3. The program’s TR-3 upgrade consists of a $1.9-billion suite of new hardware and software technologies that will enable many Block 4 capabilities. TR-3 provides improved processing capability and increased memory capacity compared with the current F-35 processor and memory system, known as Technology Refresh 2.[13] In May 2024, we reported that TR-3 development faced setbacks including supply chain and software issues that were driving late aircraft deliveries and hindering the program’s progress in fielding new Block 4 capabilities.[14]

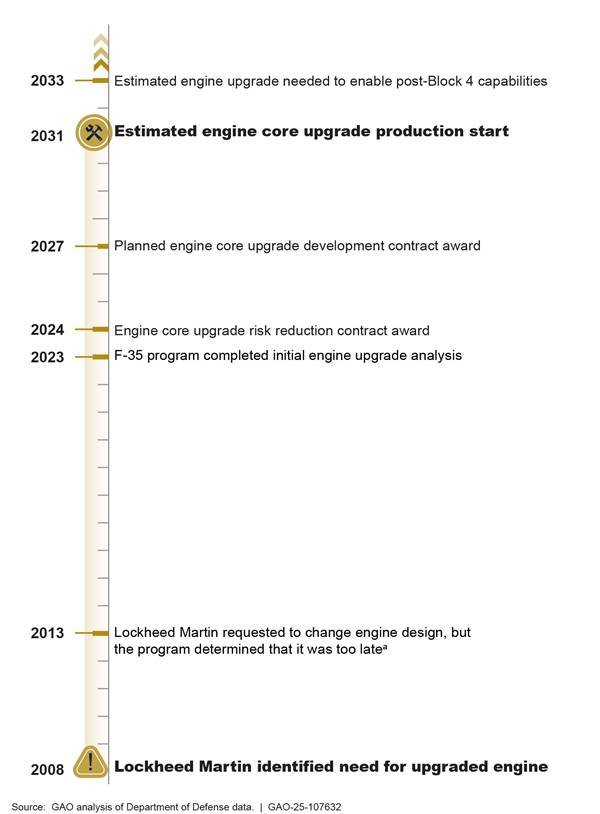

Engine and power thermal management. The program is also pursuing efforts to modernize the F-35 engine and power thermal management subsystems, which are intended to address problems the program identified back in 2008. For example, the addition of Block 4 and future modernization capabilities will require more power and cooling than the program originally projected. As a result of these power and cooling shortfalls, the engine must work harder than the contractors originally intended, reducing its overall life expectancy. Program officials estimate that the associated increased wear and tear on the engine has added $38 billion to the program’s life-cycle cost estimate.

In May 2023, we reported that the program was assessing some engine power and cooling improvement options, but it had not fully defined the requirements for how much future power and cooling the aircraft will need. We made six recommendations aimed at improving engine and power thermal management modernization efforts. DOD is taking steps to implement some of them.[15]

We previously reported in depth on Block 4, TR-3, and engine modernization. For more information, see the list of our related products at the end of this report.

Limited Block 4 Progress Adds Years to Schedule

DOD is establishing a new major subprogram for Block 4 but has made limited progress with completing TR-3 hardware and software development since we reported last year. DOD is redefining the Block 4 subprogram and F-35 officials expect it will be comprised of fewer capabilities than the original plan for Block 4, deferring development of some capabilities to a future effort. DOD expects to finish the reduced Block 4 subprogram in 2031, about 5 years later than it originally reported it would take to complete the whole Block 4 effort. According to program officials, Lockheed Martin plans to begin delivering combat-capable aircraft with TR-3 that will enable Block 4 capabilities in 2026, a 3-year delay due to hardware and software issues.

New Subprogram Is Redefining and Reducing Block 4 Capabilities

After years of managing the Block 4 and TR-3 development efforts as a part of the broader F-35 aircraft acquisition program, DOD is taking steps to manage them as a new major subprogram. In December 2023, Congress directed DOD to manage all Block 4 and TR-3 elements collectively as a major subprogram, with separate cost, schedule, and performance metrics from the broader F-35 aircraft acquisition program, which was in line with our prior recommendation.[16] The program expects to finalize the acquisition planning documents establishing the Block 4 major subprogram in the fall of 2025. As a major subprogram, DOD will have improved insight into Block 4 cost, schedule, and performance, allowing it to make more informed decisions about the modernization effort.[17]

According to program officials, the new major subprogram will follow DOD’s current acquisition policy, the Adaptive Acquisition Framework, likely through a hybrid of major capability and software acquisition pathways.[18] Using these pathways provides the program an opportunity to tailor the reporting and documentation requirements, which is intended to make the acquisition process more effective.

According to program officials, the new Block 4 major subprogram will have fewer capabilities, will experience schedule delays, and will have unknown costs until the program office finishes developing its cost estimate.

Fewer capabilities. Program officials expect to deliver fewer capabilities, generally reducing the content of the Block 4 major subprogram from how DOD has presented it in past years. As we reported in May 2024, the program office has changed the scope of the Block 4 effort multiple times, including removing and adding capabilities.[19] In 2023, the F-35 program office decided to reevaluate Block 4 to identify which capabilities it could realistically deliver in the Block 4 major subprogram. Its decisions were based on technology maturity, funding availability, and input from the military departments and international partners on their highest priority capabilities.

Based on that reevaluation, officials stated that the major subprogram will consist of a subset of the original 66 Block 4 capabilities and those added in later years, and delay or remove those not included in the subprogram. Under the new subprogram, Block 4 capabilities will include electronic warfare, weapons, communication, and navigation, among others. Program officials noted that the subprogram will delay some capabilities—including those that require an upgraded engine to function—to future modernization efforts. Program officials stated that they will also remove others that no longer meet warfighter needs.

According to officials, the program plans to formalize Block 4 major subprogram acquisition documentation in the fall of 2025, which will include the list of approved Block 4 capabilities. As of May 2025, program officials were not able to provide us with the list of approved capabilities.

Schedule delays. Program officials anticipate completing the reduced Block 4 subprogram by 2031 at the earliest, 5 years later than originally planned, with further delays for capabilities that the program pushed to future undefined modernization efforts. In 2018, the program reported that it planned to deliver the original 66 Block 4 capabilities by 2026. In May 2024, we reported that the program had revised the content of Block 4 and extended the completion date to 2029.[20] To help inform the program’s reevaluation of the Block 4 effort, DOD commissioned a review to assess the feasibility of completing Block 4. In 2024, the review team determined that the program would not deliver many Block 4 capabilities to the fleet until the mid-2030s, in part due to technical feasibility. Program officials stated that they will limit the capabilities of the reduced Block 4 subprogram to those that can be delivered by 2031 and are not dependent on engine and power thermal management upgrades. According to program officials, the program intends to deliver more of the original Block 4 capabilities in future development efforts that the program has not defined.

Unknown costs. The estimated costs for the reduced Block 4 major subprogram are currently unknown and program officials stated that a new cost estimate is not expected to be completed until later in 2025. Block 4 costs have already grown more than 50 percent over the original baseline (which included more capabilities), from $10.6 billion to $16.5 billion, as of 2021. We previously attributed Block 4 cost growth to expanded scope, development delays, testing and lab upgrades, and a lack of a sound business case.[21] A sound business case better informs the program of the cost, schedule, and technical risks associated with the effort. Until the program completes the new estimate, it is unclear how costs will change from its most recent 2021 Block 4 estimate of $16.5 billion.[22]

Program officials acknowledge that the new Block 4 major subprogram does not meet the intent of the original Block 4 effort. However, their goal is to structure the new subprogram to be executable within the newly defined cost, schedule, and performance goals. Officials stated that the changes are intended to allow the program to deliver capabilities to the warfighter at a more predictable pace.

Contractor Further Delayed TR-3 and New Capability Deliveries

According to program officials, Lockheed Martin expects to begin delivery of the TR-3 hardware and software that will enable some Block 4 capabilities in 2026, about 3 years behind schedule. See figure 1.

Program officials identified several hardware and software issues that are driving the protracted TR-3 delays, including:

· Integrated core processor. The immature design of the integrated core processor—a key TR-3 hardware component that supports the F-35’s information requirements—drove some of these delays, but it is now mature. Due to the design’s immaturity, the supplier delivered fewer integrated core processors than planned and delivered them late and with quality issues. Lockheed Martin officials stated that they increased both testing capacity and oversight of the supplier to address design immaturity and production issues. As of July 2025, program officials stated that they have fully matured the integrated core processor, and it is no longer driving TR-3 delays.

· Next Generation Distributed Aperture System. The program estimates that Next Generation Distributed Aperture System will not be complete until 2026, making it a key driver for TR-3-enabled capability delays. This system is a critical TR-3 sensor suite, which provides the pilot with a comprehensive, real-time view of the operational environment and detects threats, like missiles. The program is still in the process of testing and verifying this system.

· TR-3 software. Developmental delays with the software that enables TR-3 to function on the F-35 have continued. Program officials stated that the software that runs TR-3 has experienced stability issues—the ability of software to remain functional and consistent over time. Software testing revealed stability issues both on the ground and in-flight, including problems with radar and cockpit display systems. For example, test pilots found that TR-3 software did not reliably start up due to a combination of software and hardware flaws. Lockheed Martin is currently conducting software maturation efforts to identify and address these defects.

The program provisionally accepted aircraft that are non-combat-capable to mitigate the TR-3 hardware and software delays, among other things. We reported in May 2024 that U.S. military departments were not accepting aircraft without the TR-3 hardware and software and, as a result, Lockheed Martin parked aircraft at its facilities to await the required hardware and software.[23] To mitigate the risk of having potentially over 100 F-35 aircraft parked on contractor facilities, the program decided to provisionally accept non-combat-capable aircraft with TR-3 hardware in July 2024. Program officials stated that this approach allowed Lockheed Martin to address the stability issues, allowed the aircraft to be flown away from storage at the contractor facility, and provided the military departments with aircraft that would be used for training purposes while Lockheed Martin develops further software upgrades to add combat capability. We discuss this in more detail in the next section of this report.

Ongoing Production Issues Result in Late Deliveries and Aircraft That Do Not Fully Meet Specifications

The F-35 program continues to experience late deliveries and quality issues. Specifically, the contractors delivered all engines and aircraft late in 2024, in part due to TR-3 delays and parts shortages. In addition, the contractors continue to deliver engines and aircraft that do not fully meet contract specifications. The program, however, does not have a mechanism to comprehensively track information, such as time frames and costs, to address these deviations from contract specifications. Collectively, the contractors have received hundreds of millions of dollars in incentive fees even though they are delivering engines and aircraft increasingly late.

Contractors Continue to Deliver Engines and Aircraft Late

Both Pratt & Whitney and Lockheed Martin delivered all engines and aircraft late in 2024, and deliveries have been increasingly late over the past several years.

Engine

In 2024, Pratt & Whitney delivered all 123 engines late due to production and supply chain issues. For example, suppliers are delivering parts late, which is delaying the start of engine production by 4 months. In addition, Pratt & Whitney delivered engines an average of 68 days late in calendar year 2023 and 155 days late in calendar year 2024—a worsening trend over the last 3 years. Figure 2 provides a summary of on-time and late deliveries of engines.

Defense Contracting Management Agency officials who oversee production have issued several corrective action requests to Pratt & Whitney to improve on-time delivery, but delivery results have not improved. In April 2024, the Defense Contracting Management Agency issued a more significant corrective action request because the actions Pratt & Whitney previously identified to improve on-time deliveries were not effective. In August 2024, to mitigate these delays, Pratt & Whitney responded with another plan that aims to improve supplier issues by focusing on supplier quality and investing in supply chain capacity expansion. While the Defense Contract Management Agency reported some engine quality improvements, the contractor continues to deliver engines late. These late engine deliveries have not yet affected aircraft production.

Aircraft

Lockheed Martin delivered all 110 aircraft late in 2024 due to TR-3 hardware and software delays and continuing parts shortages. Additionally, the average number of days each aircraft was late grew from 61 days in calendar year 2023 to 238 days in calendar year 2024 (see figure 3).

While Lockheed Martin has made progress delivering aircraft in 2025, most of these aircraft were on contract to be delivered in prior years. As of May 2025, Lockheed Martin had delivered 80 aircraft in 2025, including 74 that were expected to be delivered in 2023 and 2024. Lockheed Martin still needs to deliver another 20 aircraft that it should have delivered in 2024.

Recent late deliveries are largely due to TR-3 delays and parts shortages.

TR-3. As we noted above, Lockheed Martin is taking longer to develop, test, and deliver TR-3 hardware and software, which program officials stated was the primary driver of late aircraft deliveries in 2024. To mitigate late aircraft deliveries, the F-35 program began provisionally accepting deliveries in July 2024 of non-combat-capable aircraft with TR-3 hardware installed. The program is withholding approximately $5 million for each aircraft delivered in a non-combat-capable configuration. DOD will release a portion of these withheld payments when Lockheed Martin meets certain criteria, such as validating that weapons work or completing the integrated core processor. In the meantime, the military departments are using the non-combat-capable aircraft for training and the program plans to begin updating these aircraft with limited combat-capable software in July 2025.

Program officials stated that they are accepting non-combat-capable TR-3 aircraft because having potentially over 100 aircraft parked at contractor facilities waiting for delivery of TR-3 combat-capable software was too risky, among other reasons.[24] Lockheed Martin continued production while storing aircraft in long-term parking as they awaited TR-3 software. As of May 2025, program officials stated that they had accepted 174 non-combat-capable TR-3 aircraft, which includes all aircraft that were in long-term parking due to TR-3 delays. However, as we noted above, the contractor needs to deliver aircraft that it should have delivered in 2024.

Parts shortages. Lockheed Martin continues to experience parts shortages, which have also contributed to late aircraft deliveries. These shortages have caused an accumulation of aircraft in the final stage of the production line while they await late parts. For example, in February 2025, according to program officials, the production line could not accommodate 52 aircraft that were awaiting parts. As a result, the contractor had to store these aircraft until those parts arrived and could be installed. Further, as of February 2025, the Defense Contract Management Agency reported that there were more than 4,000 parts shortages in this final stage of the production line, which was two times the historic average.[25] For example, the flap on the front of the wing has been a key driver of production delays since 2023. According to program officials, these parts, which are produced by Lockheed Martin, continue to delay or introduce inefficiency into the production process. In addition, more than 1,600 of these parts shortages were related to TR-3 hardware. According to Defense Contract Management Agency officials, Lockheed Martin has plans in place to address parts shortages, such as working with suppliers to identify risks to the supply chain earlier. However, parts delays and shortages will contribute to late deliveries through 2025.

For several years, we have reported that ongoing supply chain issues are a major factor causing an increase in parts shortages for production and sustainment, leading to work being performed out of its assigned production station, creating additional risk of late deliveries, and affecting maintenance activities.[26] In 2021, we testified that the F-35 program was planning to increase production rates even though it had not addressed longstanding supply chain issues that strained production.[27] Aircraft suppliers also produce parts to support sustainment, which the program uses for aircraft maintenance. In April 2024, we reported that spare parts shortages for sustainment negatively affect the F-35’s ability to fight and meet the demands of its missions.[28] Although Lockheed Martin takes actions to improve supplier issues, supply chain problems continue to occur every year.

Our prior work has found that using evidence and applying learning is key to effective decision-making.[29] Specifically, using evidence can help an organization better understand why desired results were not achieved. This, in turn, informs decision-makers so they can change their approach to achieve better outcomes.

The F-35 program has not adjusted procurement quantities based on the evidence of what suppliers can support—which, in turn, affects contractor production capacity—and instead plans to increase production rates in the near term. The program annually reviews its planned production quantities as part of its overall budget preparations. The long-term production planning profile does not show a reduction in production until 2032. Program officials stated that the maximum production capacity is 156 aircraft per year, but the contractor has not been able to meet the current lower demand of 153 aircraft. As noted above, Lockheed Martin delivered 110 aircraft in 2024, all of which were late. The F-35 program continues to be optimistic about the contractor’s capacity to meet its delivery schedules and has not adjusted procurement quantities to reflect the evidence that aircraft deliveries are increasingly late. Furthermore, the program’s decision to continue to plan for high rates of production even though TR-3 was not ready has contributed to the military departments needing to accept non-combat-capable aircraft, meaning the aircraft cannot be used to perform their core combat-related missions. Additionally, as the program delivers more aircraft to the fleet, there will be greater demand for spare parts to support F-35 operations and maintenance activities. This further exacerbates supply chain capacity issues. We recognize that changing contractually-agreed-to quantities can affect costs, but it may also free up additional funds that can be used to support higher priority needs. Until the F-35 program evaluates Lockheed Martin’s capacity to ensure that production and sustainment demands can be met and assesses the cost implications, the program is at risk of failing to meet the warfighter’s needs or maximize the use of government resources.

Information on Aircraft Deviations from Contract Specifications Is Limited

Lockheed Martin has delivered every lot of aircraft with major variance requests (MVR), which are contractor requests to deliver aircraft that do not fully meet the contract specifications. Although the number of MVRs associated with each aircraft is declining over time, Lockheed Martin continues to deliver aircraft with about 40 MVRs on average since its 10th production lot, which was delivered in 2018. Many MVRs have not been fixed and some have remained open for 15 years. As of March 2025, 475 out of 830 unique MVRs remain open, all of which the program stated that it plans to eventually close, but did not have a specific planned closure date (see figure 4).

Note: Average open MVR is the average of the identified issues still open in a particular lot. Lockheed Martin may have identified these issues in a previous lot and may carry them into the next lot if left unresolved. An open MVR means Lockheed Martin has not installed the required action to fix it on aircraft in production or has not begun to install the fix on aircraft that have been delivered. The program will close an MVR when Lockheed Martin has implemented the fix on the production line and when it starts to fix delivered aircraft. Other MVRs are closed when the program decides to accept the contract deviation and not fix the issue after negotiating other considerations, such as lower prices, from the contractor.

According to program officials, MVRs are largely due to the program’s deliberate approach to pursue concurrent development and production of the F-35—something we have reported is inconsistent with our traditional best practices for major defense acquisition programs.[30] Traditionally, best practices emphasize the importance of identifying and controlling risks with a product’s design early and managing them before committing to substantial production investments. Program officials noted that many MVRs were found during durability testing—a test that simulates long-term use of the aircraft—and sometimes during aircraft maintenance inspections or analysis. For example, Lockheed Martin discovered during testing, inspection, or analysis that some parts were:

· needing replacement before the required 8,000 flight hours;

· cracking or corroding earlier than expected;

· coming loose due to wear and tear on the aircraft; or

· not functioning as intended.

We found that the program did not fully understand the scope of the risk associated with these MVRs because the data collected and maintained by the program office have quality issues and the data are not accessible within a comprehensive database. The program’s database tracks limited information about the quantity of MVRs associated with each aircraft and the status of the MVRs (open or closed). We reviewed information in this database and found data quality issues, such as duplicate entries and misspellings. We also found that the database does not contain information on risk level, closure plans, and the costs and timelines to fix the MVRs. Furthermore, when we asked program officials about these issues, they stated that they could provide specific information on each MVR but had not assessed these data collectively. Program officials stated those data are located in hundreds of individual documents and not summarized in the MVR database. Program officials stated that most MVRs are low risk, all MVRs have closure plans, and costs are negotiated with Lockheed Martin, but they could not provide data to support these statements. In June 2025, the F-35 program requested over $283 million to correct some aircraft defects and deficiencies associated with MVRs, among other things. See figure 5 for a depiction of what information is in the program’s MVR database as opposed to what information is within hundreds of separate documents.

Because MVR information is in hundreds of individual documents and the existing database has quality issues, the F-35 program does not understand the magnitude of risk, schedule implications of the closure plans, or cost that these MVRs collectively pose. Internal controls for the federal government state that a program should use quality information to achieve the entity’s objectives.[31] Quality information is appropriate, current, complete, accurate, accessible, and provided on a timely basis. The program’s database, however, is not accurate and does not contain complete information. Without a comprehensive mechanism to track MVRs that is based on quality information, officials will not have key information needed to understand and manage the collective risks, closure plans, and costs associated with MVRs.

In contrast to the relatively large numbers of aircraft MVRs, Pratt & Whitney identified seven MVRs on the engine in 2024. Although there are fewer engine MVRs than aircraft MVRs, the engine contractor is still not delivering engines to contract specifications after nearly 20 years of production. In 2015, the DOD Inspector General conducted an F-35 engine quality assurance inspection and recommended that the program evaluate open MVRs to determine whether specification changes are required and if achievable closure plans can be developed, among other things.[32] At that time, the F-35 program office disagreed with evaluating open engine MVRs, stating that the engine program was still in development. In May 2025, program officials stated that, similar to aircraft MVRs, they plan to eventually close all engine MVRs, but were unable to identify a planned closure date.

Contract Incentives Are Not Improving Production Outcomes

The F-35 program office uses various contract incentives aimed at improving program outcomes, including on-time deliveries. In the case of the F-35, engine and aircraft contractors can be compensated in multiple ways. First, contractors earn a base profit, which is calculated as a certain percentage of the cost of the engine or aircraft. Second, on top of the base profit, the contract can include the payment of additional fees to incentivize the contractors to identify opportunities to reduce the cost of developing and producing the engine or aircraft. Third, the contract may also include fees or penalties to incentivize the contractors to achieve various performance objectives, such as reducing the overall time it takes to build an engine or aircraft, or deliver them on time.

The F-35 program office compensated Lockheed Martin with hundreds of millions of dollars of performance incentive fees while the percentage of aircraft delivered late and the average days late grew.[33] For aircraft produced in lots 13 and 14, which were delivered between 2021 and 2024, the program included performance incentive fees to drive Lockheed Martin’s performance in certain areas, including delivering aircraft on time.[34] The lot 12-14 contract allows Lockheed Martin to earn a portion of the fees for aircraft delivered up to 60 days late, with the fee decreasing every day the aircraft is late.[35] Lockheed Martin earned a large percentage of the on-time delivery performance incentive fee for lots 13 and 14 although it delivered aircraft late, as shown in figure 6.

Figure 6: Lockheed Martin Earned Millions for On-Time Delivery of U.S. Aircraft, Even Though It Delivered Aircraft Late

Note: Percentage of incentive fee earned reflects the total on-time delivery incentive fee earned out of total on-time delivery incentive fee available for the entire production lot of aircraft delivered on time and late.

While the program originally targeted lot 15 incentives to on-time delivery, once officials knew the contractor would not be able to earn those incentives, the program repurposed the incentive fees. A portion of the lots 15-17 contract incentive fee was designed to incentivize on-time delivery. Defense Contract Management Agency officials projected that under the lots 15-17 contract incentive fee structure, Lockheed Martin would not earn the vast majority of the fee because of the TR-3 delays we described above. Withholding this fee altogether would have saved taxpayers millions of dollars; however, the program modified the contract, which allowed Lockheed Martin to earn some of the incentive fee that it would have otherwise not earned. The program repurposed the unearned on-time delivery incentive fee to target some of the issues that it believed were driving the late deliveries of aircraft in lots 15-17. For example:

· The program redirected over a hundred million dollars of unearned incentive fees to Lockheed Martin to pay for improved software lab capacity, and

· The program repurposed over a hundred million dollars of unearned incentive fees to pay Lockheed Martin to address repairs and hardware of TR-3, Next Generation Distributed Aperture System, and to fund TR-3 test stands—special tooling to improve production processes.

Pratt & Whitney also earned tens of millions of dollars in incentive fees even though it was partially penalized for delivering engines increasingly late.[36] The F-35 program negotiated an incentive fee structure for the engine that allowed the contractor to earn more money if engines passed specific quality tests and if it kept total assembly time down. This incentive fee structure is intended to encourage the contractor to improve engine quality while also reducing the hours its takes to build engines, keeping engine costs down and increasing the likelihood that engines are delivered on time. The incentive structure also included penalties that reduced the total amount of fee Pratt & Whitney could earn based on how late it delivered engines. Pratt & Whitney earned between 37 and 78 percent of the total incentive fee available for production lots 14 through 16, equating to tens of millions of dollars, because it performed well on both the quality tests and assembly time metrics. The total amount of incentive fee earned for engines delivered across those production lots was reduced by over $10 million because it delivered nearly all engines late. However, Pratt & Whitney earned tens of millions of dollars in incentive fees because the value of the fees it earned for keeping total assembly time down more than offset the penalties levied on it for delivering engines late. This incentive structure and late delivery penalty was not effective at improving on-time deliveries (see figure 7).

Note: Data reflect total engine incentive fees, including quality tests, time to assemble the engine, and penalties for late delivery for U.S. military departments, partner nations, and foreign military sales customers. Percentage of incentive fees earned reflects the total fee earned out of total fee available for the entire production lot of engines delivered on time and late.

In July 2017, we reported that DOD uses contract incentives as one of the ways it can promote desired acquisition outcomes, such as keeping costs low, delivering a product or service on time, or achieving certain technical results.[37] Based on our prior work examining defense acquisitions, when structured correctly, the use of contract incentives can more closely align contractor motivations with the government’s desired outcomes. Our prior work, however, has shown that if not well managed, the use of contract incentives can lead to unnecessary costs shouldered by the American taxpayer, among other problems.[38]

The F-35 program’s use of incentive fees has largely been ineffective at holding the contractors accountable to delivering engines and aircraft on time. The engine and aircraft production contracts include delivery time frames that the contractors are required to meet. DOD guidance states that incentive fees can be used to achieve the desired schedule.[39] The program’s use of incentive fees, tied in part to on-time deliveries, has not achieved schedule goals. Further, for lot 15 aircraft, where the program originally tied incentives to on-time delivery, the program gave the contractor a second chance to earn fees by redirecting those incentives to other aspects of the program when it was clear that Lockheed Martin would not deliver any aircraft on time. Unless the F-35 program reevaluates its use of incentive fees and better aligns them to achieving desired production schedule outcomes, it will be at greater risk of continuing to reward contractors for delivering engines and aircraft late.

F-35 Program Has Awarded Predevelopment Contracts but Has Not Selected an Acquisition Pathway for New EPM Subprogram

The F-35 program office awarded two predevelopment contracts for its engine and power thermal management modernization (EPM) major subprogram but has not selected an acquisition pathway to manage it. Specifically, the program awarded a contract to Pratt & Whitney to continue risk reduction efforts to mature the overall design and technologies of the engine’s power module, known as the engine core upgrade. The program also awarded a contract to Lockheed Martin to analyze potential solutions for upgrading the power thermal management system and related subsystems, known collectively as the power thermal management upgrade (PTMU). At the same time, the F-35 program has taken steps toward formally designating the EPM effort as a major acquisition subprogram but has not identified which acquisition pathway it will use to manage the major subprogram, which is required by DOD’s current acquisition policy.[40]

F-35 Program Awarded Contracts to Continue EPM Predevelopment Efforts

The F-35 program office awarded two contracts—one to Pratt & Whitney and one to Lockheed Martin—so that the contractors would continue risk reduction efforts to mature the overall design and technologies of the engine core upgrade and to analyze potential solutions for the PTMU.

· The engine core upgrade will improve the power module, including the gearbox—two components of the current engine that work in tandem to produce and extract more power from the engine. According to the program, the engine core upgrade will support all three aircraft variants, reduce overall life-cycle costs, restore the life of the current engine, enable future mission system capability growth, and require minimal changes to the existing support infrastructure.[41]

· The PTMU effort will modernize the power thermal management system and related subsystems, including the fuel thermal management and electrical power systems.[42] Specifically, the effort will provide sufficient power and cooling for existing subsystems and support future growth of mission system capabilities, like the radar. Further, the PTMU effort will help meet the aircraft’s planned service life.

Engine Core Upgrade

In May 2024, the program identified several risks to the development of the engine core upgrade at the preliminary design review.[43] Although the review validated that the design met expectations, it also noted major risks, such as the following:

· lack of integrated development and test schedules between the engine and the aircraft;

· parts not arriving in time to support testing; and

· immature test plans.

To address these risks, the program awarded a $1.3 billion risk reduction contract to Pratt & Whitney in September 2024. This contract is intended to further mature technologies and reduce risk of the engine core upgrade through activities such as coordinating test schedules, procuring test hardware, and executing test plans. After the completion of the risk reduction contract at the end of 2026, the program expects to award an engine core upgrade development contract.

Further, two critical technologies related to the manufacturing of the engine turbine blade are not mature. Both have only reached technology readiness level 5, meaning that they are immature because their components have only been validated in a relevant environment. Achieving a technology readiness level 6, which is the level suggested by DOD policy and indicates that a representative model of the technology has been tested in a relevant environment, represents a major step up in a technology’s demonstrated readiness and can take time to achieve.[44] Our best practices recommend that technologies achieve a technology readiness level 7, in which the technology has been demonstrated in an operational environment, at the start of a formal program to reduce risks of cost and schedule overruns.[45] Pratt & Whitney representatives stated that they will continue to test and develop these technologies as part of the risk reduction contract.

While the Block 4 subprogram will not be dependent on upgrading the engine, engine core upgrade delays would likely contribute to more delays with delivering post–Block 4 capabilities. In May 2024, we reported that post–Block 4 capabilities and mission systems that the program expected to deliver in 2029 would need the new engine upgrades. Since then, the program revised its time frames for delivering those post–Block 4 capabilities that are dependent on these upgrades to 2033. Program officials attributed these further delays to their improved understanding of the development schedule and availability of flight test assets. According to the program, production for the engine core upgrade is expected to start in 2031. We previously reported that the program identified the need for additional power and cooling in 2008.[46] Figure 8 illustrates the timeline for the engine core upgrade.

aProgram officials determined that it was too late to redesign the engine given the cost and schedule effects of such a change because the program had completed design and verification activities.

Power Thermal Management Upgrade

In December 2024, the F-35 program awarded a $107 million contract to Lockheed Martin to analyze the options for upgrading subsystems of the PTMU. Specifically, Lockheed Martin will conduct studies that evaluate:

· the cooling capacity of the current power thermal management system;

· alternatives for a new power thermal management system or upgrading the current system;

· trade-offs for modernizing related subsystems, including the electrical power system and fuel thermal management system, that may be needed to provide power and cooling to post–Block 4 capabilities; and

· how the engine core upgrade will be integrated onto the F-35 aircraft.

After it completes the 2-year analysis in December 2026, Lockheed Martin plans to present options for the PTMU to F-35 program officials, who will make a final decision on which systems to upgrade or modify. In choosing a solution, the program will consider the technology maturation of the potential options, as well as their ability to affordably retrofit the existing fleet, among other factors. According to program officials, a new power thermal management system would likely cost more and take longer to develop than an upgraded power thermal management system; however, the costs and schedule of potential PTMU solutions are unknown. Program officials stated that there is presently no preferred solution and all viable options that meet the cooling requirements are being considered. The program plans to begin design efforts once it selects a PTMU solution in December 2026 and expects PTMU development to begin in 2027.

As we reported above, delays to the PTMU effort would likely affect the Block 4 capability delivery schedule. Currently, the program plans to begin production of the PTMU in 2033, the same year that post–Block 4 capabilities will require the increased power and cooling, providing limited, if any, time for schedule delays should they occur (see figure 9).

aProgram officials determined that it was too late to redesign the engine given the cost and schedule effects of such a change because the program had completed design and verification activities.

F-35 Program Is Establishing EPM Subprogram but Has Not Selected an Acquisition Pathway

The F-35 program is taking steps to establish the EPM effort as a major acquisition subprogram, but has not chosen which acquisition pathway it will use to manage the subprogram.[47] The program will establish the engine core upgrade as part of the subprogram first, followed by the PTMU. This is due to the engine core upgrade effort being further along than the PTMU, as noted above.

· First, the program plans to formally designate the engine core upgrade as part of the EPM major subprogram at the end of calendar year 2025. Program officials are in the process of establishing an acquisition program baseline for the engine core upgrade, which will include cost and schedule estimates. They are also developing acquisition planning documents, including an acquisition strategy, cost estimate, and test plan.[48]

· Second, the program will add the PTMU to the EPM major subprogram’s acquisition program baseline in late 2028, after completing a 2-year analysis to determine potential solutions for the PTMU. Prior to adding the PTMU to the acquisition baseline, the subprogram plans to develop PTMU acquisition documents, including cost and schedule estimates.

The F-35 program does not plan to choose an acquisition pathway to manage its new EPM major subprogram, which does not adhere to DOD’s current acquisition policy.[49] In 2020, DOD established the Adaptive Acquisition Framework with the intent to more quickly deliver innovative technologies to the warfighter. Under this framework, new major subprograms, like the EPM, are to select an acquisition pathway, which provides the program the opportunity to use acquisition processes that match the characteristics and risk of the capability being acquired. However, according to program officials, the EPM major subprogram does not intend to follow the Adaptive Acquisition Framework and select a matching acquisition pathway.

Instead, officials stated that they plan to manage the EPM major subprogram within the broader development program for the F-35, which follows the previous, now rescinded, DOD acquisition policy.[50] Furthermore, the broader F-35 aircraft acquisition program is now in sustainment and is governed by sustainment policies instead of policies that govern development activities.[51]

Should the F-35 program continue with this approach, there will be no mechanism in place to ensure that the EPM major subprogram completes acquisition documentation that DOD needs to conduct appropriate oversight and make fully informed funding decisions. Without selecting an appropriate acquisition pathway, the subprogram will miss opportunities to take advantage of the flexibilities offered in the Adaptive Acquisition Framework. Further, acquisition pathways allow the program to tailor the reporting and documentation requirements, which is intended to make the acquisition process more efficient.

F-35 Program Has Opportunities to Expand Use of Leading Practices for Product Development

The F-35 program has opportunities to expand the use of leading practices for product development and formalize them in acquisition documentation as it stands up the Block 4 and EPM major subprograms. In 2023, we reported that leading companies employ an iterative process of design, validation, and production to quickly develop and deliver products.[52] Leading companies use key practices throughout these iterative cycles. For example:

· Leading companies seek and obtain continuous user feedback—feedback from the actual operators of the product—throughout the iterative cycles.

· Leading companies capture this feedback to determine if the design is meeting user needs and reflects a minimum viable product—a product with the minimum capabilities needed for customers to recognize value. A minimum viable product is not predefined before development begins; instead, it is arrived at over the course of an iterative development process.

· Leading companies use modern design tools—such as virtual representations of physical products (digital twins), modeling and simulation, and digital threads—throughout development for both hardware and software. Leading companies also use modeling and simulation to capture information about the product’s design and feed it into the digital thread, which is a common source of information that connect stakeholders with real-time data.

Our prior work has found that companies that incorporate these leading practices are better positioned to deliver innovative products to users at rapid speed—outcomes that are consistent with the F-35 program’s acquisition goals.[53]

We found that the F-35 program has taken steps to implement some key practices that leading companies use for product development, but additional opportunities exist to expand their use in the Block 4 and EPM major subprograms.

User feedback. Block 4 and EPM officials reported that they solicit feedback from users and stakeholders regularly to inform the product design. For example, program officials collect and incorporate feedback on a routine basis from U.S. military departments, partners, foreign military sales customers, and end-users to tailor Block 4 and EPM requirements. Further, EPM officials stated that they also consider user feedback to make trade-off decisions, such as increasing engine performance at the cost of engine weight. The program’s actions align with leading companies’ practice of repeatedly obtaining feedback from users and stakeholders to inform product specifications throughout design.

Minimum viable product. Block 4 officials stated they are using a minimum viable product in development, but their approach is inconsistent with leading practices. According to leading practices, companies structure the iterative development processes to identify, design, and produce a minimum viable product that satisfies the warfighters’ highest priority needs first and is able to be improved over time through subsequent iterations. The F-35 program’s actions to date demonstrate a misunderstanding of how to use a minimum viable product in iterative development.

First, program officials stated that they have delivered minimum viable products and plan to deliver them in the future. The new Block 4 subprogram plans to deliver minimum viable products by grouping the predetermined capabilities of the new Block 4 subprogram into planned increments based on military departments’ and partner nations’ priorities, technical feasibility, and cost. However, the program’s description of a minimum viable product is more aligned with traditional incremental, linear development that defines performance and technical requirements at the start. As our prior work has found, this traditional approach often results in ambitious performance requirements that are inflexible to changing mission needs and cannot be fulfilled within the time and money that an acquisition program has available.[54]

Second, in responding to our request for information on how they use a minimum viable product, Block 4 officials reported that the first TR-3 aircraft delivered was a form of a minimal viable product because it provided training capabilities. While this approach allowed the program to mitigate the risks of the extensive TR-3 developmental delays we described earlier in this report, this also resulted in the government having to pay for most of the cost of the aircraft and the military department customers having to accept aircraft that were not capable of performing combat missions. As a result, these customers were temporarily left with less valuable aircraft, while they await further software upgrades to restore combat capabilities. In contrast, leading companies proactively solicit customer priorities, identify capabilities that are technically feasible, then rapidly define, develop, and produce a minimum viable product that meets essential mission needs. If the product does not achieve this level of value, then it does not constitute a minimum viable product.

Unless the new Block 4 subprogram revises its past approach to using minimum viable products to be more consistent with leading practices for product development, the program will miss opportunities to deliver what is most important to the warfighter in time frames that reflect their needs.

Modern design tools. Both the Block 4 and EPM subprograms have plans in place to develop and use modern design tools, such as digital twins, modeling and simulation, and a digital thread.

· In 2024, the program made a $18.9 million investment in digital twin tools and a facility for use in Block 4 development, according to program officials. The F-35 program’s digital twin pilot will start in 2025 and have a limited focus, such as on development of TR-3. The program plans to expand this pilot as the digital twin tools mature. In addition, the EPM subprogram plans to develop and use a variety of digital twins during development and sustainment, such as using an engine performance model for testing. The program has the opportunity to use these tools to enable rapid, iterative development.

· The joint simulation environment is a tool that could be used for design modeling and simulation but is currently only used for testing and training. Specifically, the configuration of the joint simulation environment—a simulator that validates Block 4 capabilities in complex mission scenarios that cannot be tested in a real-world environment—is about a year behind the current configuration of the fleet, according to officials. The joint simulation environment is not currently used to inform the program’s iterative development cycle because it is not updated in real time.

Until the F-35 program expands its use of design modeling and simulation by better aligning Block 4 development and joint simulation environment schedules, it will not be able to test new capabilities in real-time, digitally representative environments. Such digital testing can identify challenges sooner, provide for more timely development changes, and avoid some physical tests. F-35 program officials stated that they are aware of the need to shorten the time frame for joint simulation environment updates and plan to work with Lockheed Martin to do so.

· Both Block 4 and EPM efforts have demonstrated interest in developing and maintaining a digital thread, which connects stakeholders with a common set of real-time data. Officials stated that the program procured the software for a digital thread in 2024 and the capability will be available for Block 4 in 2025. Additionally, EPM officials are evaluating how to use a digital thread. However, both Block 4 and EPM officials have noted significant challenges, such as high upfront costs and data and usage rights, in developing a digital thread. By further expanding the use of a digital thread, the F-35 program could facilitate more iterative development and quicker delivery of Block 4 and EPM capabilities.

As the program continues to establish the Block 4 and EPM major subprograms, it has opportunities to expand the use of leading practices for product development such as proactively defining and developing minimum viable products, pursuing digital twins that can be used to inform development, and updating modeling and simulation tools in real time. Expanding the use of leading practices improves the likelihood of delivering capabilities the warfighter needs at a more rapid pace than the program has during the first 7 years of Block 4 development. In addition, expanding the use of iterative development should result in continuous prioritization of warfighter needs to deliver a relevant product that is responsive to changing environments.

Furthermore, the program is in an advantageous position to formalize its plans to utilize leading practices as it develops the Block 4 and EPM acquisition strategies. The acquisition strategy is an integrated plan that identifies the overall approach to rapidly and iteratively acquire, develop, deliver, and sustain capabilities to meet the users’ needs.[55] Incorporating leading practices for product development into acquisition documentation provides the program with an opportunity to demonstrate a formal commitment and be held accountable to aligning with modern design approaches.

Conclusions

The F-35 remains critical to our national defense, as well as that of our partners and allies, and is expected to retain critical roles for decades to come. In our reviews of the F-35 program over the last 2 decades, we have routinely recounted cost and schedule overruns and other shortfalls. With the program now focused on production and modernization, it has an opportunity to cut a new path of greater accountability for delivering highly capable aircraft that meet warfighter needs at the pace of relevance.

After nearly 20 years of aircraft production, however, the F-35 program continues to overpromise and underdeliver. In addition, the F-35 contractors continue to have challenges with fully meeting contract requirements and the program rewards them for it.

· Supply chain challenges continue to strain engine and aircraft production schedules, leading to increasingly late deliveries. The program, however, has not accounted for these delays as it continues to direct the contractors to increase production rates. Better aligning planned production and sustainment demands with contractor and supplier capacity would facilitate the ability of contractors to deliver engines and aircraft on time and better ensure warfighters receive aircraft when planned. Continuing to plan for engines and aircraft that have not been delivered on time leaves the military departments with unmet expectations and a less capable fighting force than planned.

· Similarly, the contractors have continued to deliver engines and aircraft that do not meet contract specifications—resulting in hundreds of MVRs. The program office, however, does not have an adequate mechanism to track these MVRs. Without a comprehensive mechanism to track MVRs that is based on quality information, the program will not have key information needed to understand the collective risks, closure plans, and costs associated with MVRs.

· Finally, the program has taken considerable steps to establish and pay incentives to the contractors with the aim of improving timely delivery, among other things. Nonetheless, delivery time frames continue to worsen—but fees continue to be paid. It is increasingly important that DOD obtains real value for providing increased fees to contractors, above and beyond the profits already built into the contracts, through incentives. Better aligning incentive fee structure and payments with key goals of the program could help ensure these higher payments lead to improved outcomes for the taxpayer and the warfighter.

The program office’s actions to establish Block 4 and EPM as major subprograms demonstrate a greater commitment to developing executable modernization efforts that deliver capability to the warfighter with greater predictability, but more actions are needed.

· Program officials plan to manage the EPM major subprogram under the previous, now canceled, DOD acquisition policy used for the broader F-35 aircraft acquisition program instead of selecting an Adaptive Acquisition Framework pathway, raises concerns. Relying on the canceled policy means there is no current guidance to ensure active oversight. The Adaptive Acquisition Framework offers the opportunity to tailor the reporting and documentation requirements and capture the acquisition efficiencies espoused by DOD in creating it.

· Going forward, as the F-35 program establishes the Block 4 and EPM major subprograms, it has the opportunity to expand the use of leading practices for product development and formalize these in subprogram acquisition documentation. Using these tools could help the program get on the right path to achieve its goal of quickly delivering capabilities to the warfighter.

By working to address the issues outlined above, the F-35 program can better ensure the timely delivery of systems and capabilities to the warfighter, thus improving U.S. air superiority and national security and enhancing the capability of our partners and allies.

Recommendations for Executive Action

We are making the following six recommendations to DOD:

The Under Secretary of Defense for Acquisition and Sustainment should ensure that the F-35 program office evaluates the production capacity of Lockheed Martin to meet the planned delivery quantities on time and adjust the future schedule to better ensure production and sustainment demands can be met. (Recommendation 1)

The Under Secretary of Defense for Acquisition and Sustainment should ensure that the F-35 program office establishes a comprehensive mechanism containing quality information to track information about F-35 engine and aircraft MVRs. (Recommendation 2)

The Under Secretary of Defense for Acquisition and Sustainment should ensure that the F-35 program office reevaluates the use of incentive fees to better achieve the desired schedule for future production contracts. (Recommendation 3)

The Under Secretary of Defense for Acquisition and Sustainment should ensure that the F-35 program office selects and employs an Adaptive Acquisition Framework pathway for the EPM major subprogram. (Recommendation 4)

The Under Secretary of Defense for Acquisition and Sustainment should ensure that the F-35 program’s Block 4 and EPM major subprograms expand the use of the leading practices for product development, such as developing a minimum viable product, pursuing digital twins that can be used to inform development, and updating modeling and simulation tools in real time. (Recommendation 5)

The Under Secretary of Defense for Acquisition and Sustainment should ensure that the F-35 program formalizes its plan to incorporate leading practices for product development in its Block 4 and EPM major subprogram acquisition documentation. (Recommendation 6)

Agency Comments and Our Evaluation

We provided a draft of this report to DOD for review and comment. DOD provided written comments, which we have reproduced in appendix II. DOD concurred with four of our six recommendations and partially concurred with two recommendations. DOD also provided technical comments, which we incorporated as appropriate.

DOD concurred with our fourth and sixth recommendations and described actions it would take to address them.

DOD concurred with our first recommendation related to production quantities and third recommendation related to incentive fees and stated that it will continue to evaluate these areas, but did not identify new actions it would take to address our recommendations. In our report, we explain that the program’s actions taken thus far were the cause of our findings—namely that DOD has continued to seek to purchase more aircraft than have been delivered on time and meet contract specifications and that incentive fees continued to be awarded despite outcomes not meeting expectations. Therefore, we do not believe that continuing the past practices is likely to lead to different, or preferably better, results. We continue to believe that additional steps, as discussed in our report, will be necessary to fully implement our recommendations.

DOD partially concurred with our second recommendation to establish a comprehensive mechanism to track F-35 engine and aircraft MVRs. In its response, DOD stated it will conduct a review to assess options for development of a comprehensive mechanism to track information about F-35 aircraft and engine MVRs. Assessing options for the development of a tracking mechanism is a good first step. However, establishing a comprehensive mechanism to track MVRs that is based on quality information, as we recommend, will ensure that officials have key information to understand and manage the collective risks, closure plans, and costs associated with MVRs.

DOD also partially concurred with our fifth recommendation to expand the use of leading practices for product development. In its response, DOD stated that it will continue to evaluate opportunities to add programmatic and engineering rigor and incorporate leading practices into F-35 development efforts, which is in alignment with our recommendation. DOD identified instances in which our leading practices for product development are not applicable, specifically regarding using a minimum viable product for the EPM subprogram due to the nature of the highly integrated technical solutions. DOD noted, however, that it will continue to employ digital engineering practices in EPM development to the greatest extent practicable.

We understand DOD’s concerns about broadly applying a minimum viable product across the multifaceted EPM effort, but believe progress is possible and preferable to the current course. In particular, we continue to believe that there are opportunities to expand the use of leading practices for product development across the Block 4 and EPM subprograms, including roles for applying minimum viable product-type approaches to some facets of the EPM effort. Iterative development came about to provide a mechanism for addressing complex development challenges. The champions of this approach, the companies from which we culled these practices, ultimately recognized that identifying what is possible and desired, in the form of a minimum viable product, followed by iterations of continuous improvement, can be preferable to extended efforts to deliver a single completed product at the end of a single protracted development cycle. Ultimately, it is up to DOD to decide in which areas of product development it is most appropriate to leverage our leading practices. By implementing our recommendation and fully embracing opportunities to expand the use of these leading practices, DOD could deliver capabilities to the warfighter at a more rapid pace.

We are sending copies of this report to the appropriate congressional committees; the Secretary of Defense; the Under Secretary of Defense for Acquisition and Sustainment; the Secretary of the Air Force; the Secretary of the Navy; and the Commandant of the Marine Corps. In addition, the report is available at no charge on the GAO website at www.gao.gov.

If you or your staff have any questions about this report, please contact me at ludwigsonj@gao.gov. Contact points for our Offices of Congressional Relations and Public Affairs may be found on the last page of this report. GAO staff who made key contributions to this report are listed in appendix III.

Jon Ludwigson

Director, Contracting and National Security Acquisitions

List of Committees

The Honorable Roger Wicker

Chairman

The Honorable Jack Reed

Ranking Member

Committee on Armed Services

United States Senate

The Honorable Mitch McConnell

Chair

The Honorable Christopher Coons

Ranking Member

Subcommittee on Defense

Committee on Appropriations

United States Senate

The Honorable Mike Rogers

Chairman

The Honorable Adam Smith

Ranking Member

Committee on Armed Services

House of Representatives

The Honorable Ken Calvert

Chairman

The Honorable Betty McCollum

Ranking Member

Subcommittee on Defense

Committee on Appropriations

House of Representatives

The National Defense Authorization Act (NDAA) for Fiscal Year 2020 includes a provision for GAO to submit a report on the F-35 program’s production and Block 4 progress within 30 days of the President’s budget submission for fiscal years 2021 through 2025.[56]

In this report, we assess (1) the Department of Defense’s (DOD) progress with Block 4 modernization efforts, (2) the extent to which contractors delivered F-35 engines and aircraft within contract time frames and specifications, (3) DOD’s progress in establishing a major subprogram to modernize the F-35 engine and related subsystems, and (4) the F-35 program’s use of leading practices for product development.

To conduct this work, we interviewed officials and representatives from the F-35 joint program office; conducted site visits and toured production facilities at Pratt & Whitney (prime engine contractor) and Lockheed Martin (prime aircraft contractor); and met with the Defense Contract Management Agency at each prime contractor location. In these interviews, we discussed aircraft production and manufacturing, modernization efforts, the engine, and the power thermal management system.